Aikace-aikace da halaye na porous chuck tebur

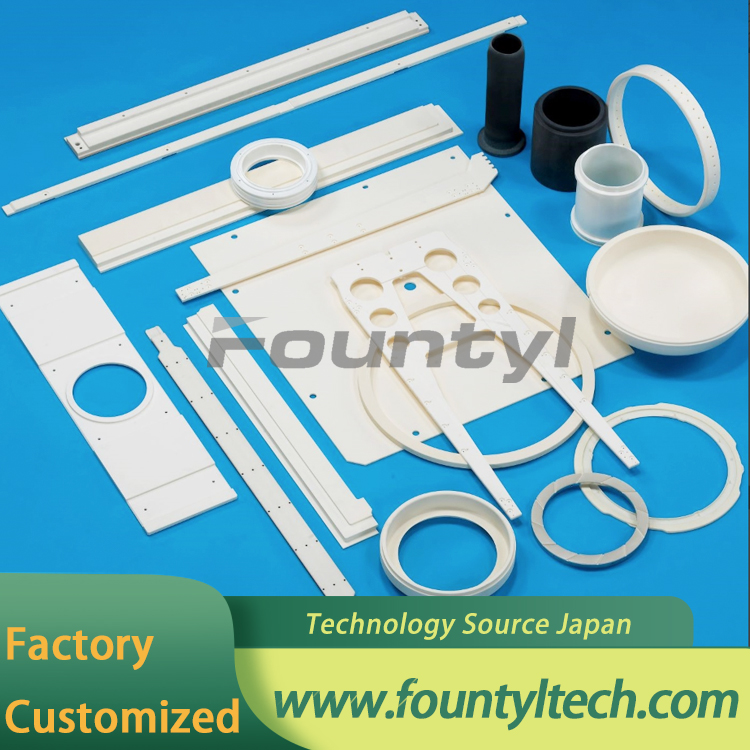

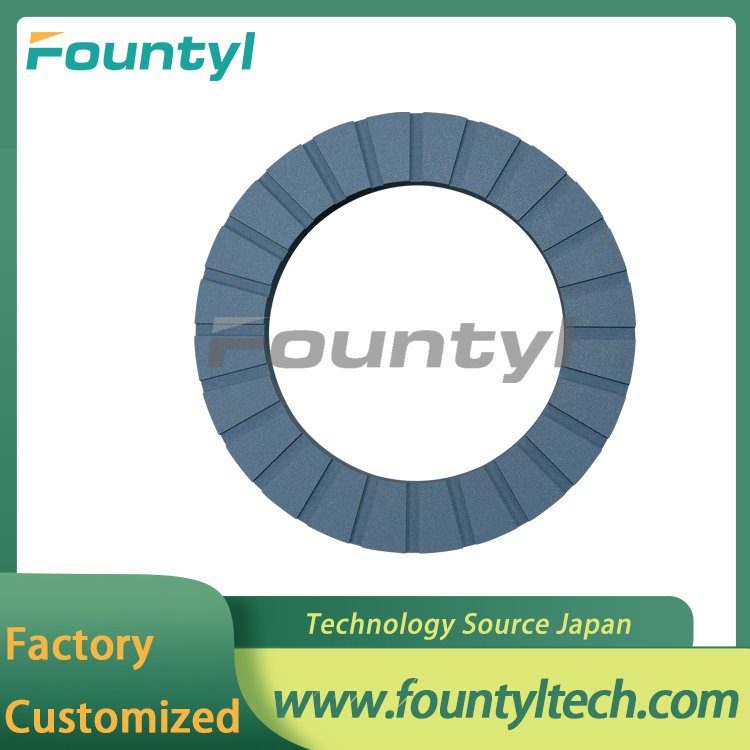

Tukwalwar tukwane tukwane ne masu ramuka da yawa a cikin kayan kanta ta hanyar fasahar sintering yumbu, kuma ana amfani da su a cikin masu tsotsa. Kwanan nan, an yadu amfani da matsayin tushe abu ga daban-daban masana'antu kayayyakin, kamar tacewa, refractories, kiln wares, absorbers, sauti absorbers, nauyi tsarin kayan, rufi kayan, da dai sauransu Musamman, shi ne amfani da injin sha fasahar tare da. high daidaito da kuma high injin. Yana da ikon ɗaukar abubuwa masu bakin ciki, wanda kwanan nan ake buƙata don samar da semiconductor, LED da nuni. Yana da matukar mahimmanci cewa yumbu mai laushi yana da babban porosity kuma yana kula da babban ƙarfi. Musamman a cikin semiconductor da masana'antar allon nuni, yumbu mai ƙyalli ya kamata su sami porosity iri ɗaya da ƙaƙƙarfan yanayin ƙasa don kada su lalata abin sha. Porous yumbu mai tsotsa yana da sunaye daban-daban masu zuwa:

1. Ceramic injin tsotsa

2. Teburin iska mai iyo

3. Porous yumbu injin tsotsa

4. Madaidaicin yumbu na gida adsorption vacumm sucker

5. yumbu injin tsotsa mai numfashi

6. Tebur yumbu mai yumbu mai yumbu

7. Madaidaicin yumbu mai ƙyalli na gida mai tsotsa

8. Teburin iska mai iyo

9. Tebur yumbu mai yumbu mai yumbu

Ƙa'idar aiki na yumbu mai yumbu mai tsotsa:

Saboda pores na porous tukwane ne sosai minutesness, a lokacin da workpiece surface aka Fitted ga injin tsotsa, shi ba zai haifar da surface scratches, dents da sauran mummuna sabon abu saboda mummunan matsa lamba. Ta hanyar haɗin ginin ƙarfe (ko yumbu) tushe da tukwane na musamman, ƙirar madaidaiciyar iska ta ciki tana ba da damar aikin aikin ya kasance mai sauƙi da ƙarfi a kan injin tsotsa lokacin da aka yi amfani da matsa lamba mara kyau.

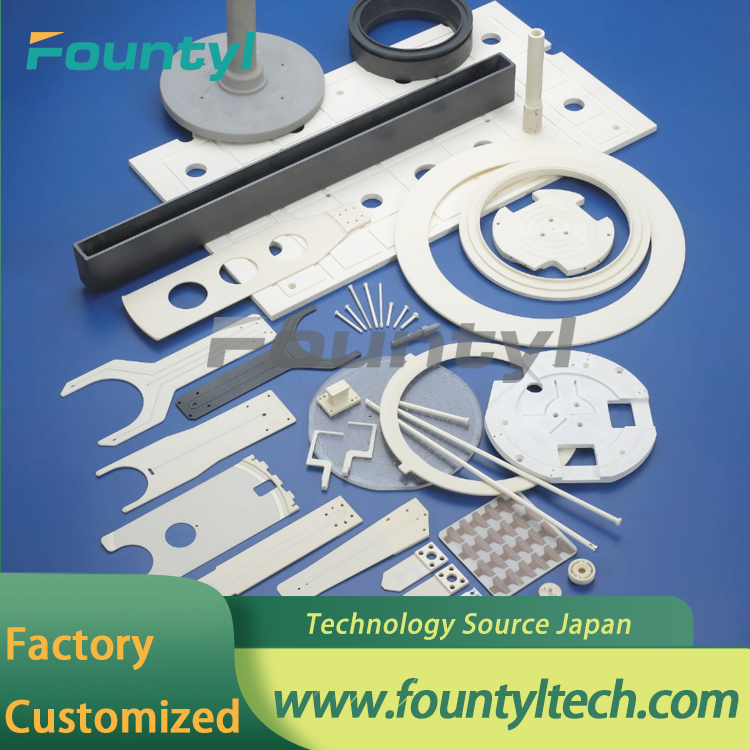

Aikace-aikace

1. Musamman yumbu injin tsotsa module don sha planar workpiece

2, Adsorption har zuwa rabin yanki ba zai karya injin ba

3, Dace a cikin yanayi mai tsabta don masana'antar injin ko masana'anta, taro ko masana'antar sarrafa kansa

4, Semiconductor wafer sucker, micro guntu kayan aiki masana'antu, yankan, nika, tsaftacewa, da dai sauransu.

5, TFT-LCD, LED kayan aiki masana'antu.

6, Exposure inji, gilashin yankan inji, gilashin substrate iska iyo kai.

7, Buga kewaye hukumar kayan aikin masana'antu.

8, Injiniyan hannu handling kayan masana'antu.

9, Ceramic Vacuum grasping module, sadaukar da kai don fahimtar aikin jirgin sama.

10, Idan za ku iya ci gaba da kama rabin yanki, to, mai riƙe yumbu ba zai rasa aikin aikin ba. mahara workpieces iya amfani da wannan yumbu chuck.

Siffofin

1, Kyakkyawan juriya mai kyau: halaye masu wuya, juriya mai juriya, ba sauƙin karce da lalacewa ba.

2, Ba sauƙin bazuwa da ƙura: yumbura gaba ɗaya sun lalace, tsari mai ƙarfi da kwanciyar hankali, babu ƙura.

3, Lightweight: haske abu da kuma ciki tsarin ne uniform porosity, musamman haske nauyi.

4, Yanki adsorption: iya sha daban-daban masu girma dabam na workpiece a kan wannan yumbu aiki surface.

5, High zafin jiki juriya, sinadaran juriya: tukwane ne high zafin jiki sintering kayayyakin, mai kyau zafi juriya da acid & alkali juriya, da fadi da kewayon aikace-aikace.

6, High lantarki yi: tare da rufi, dissipating electrostatic halaye (dangane da kayan).

7, Daban-daban masu girma dabam: kowane siffar da girman su ne ok.

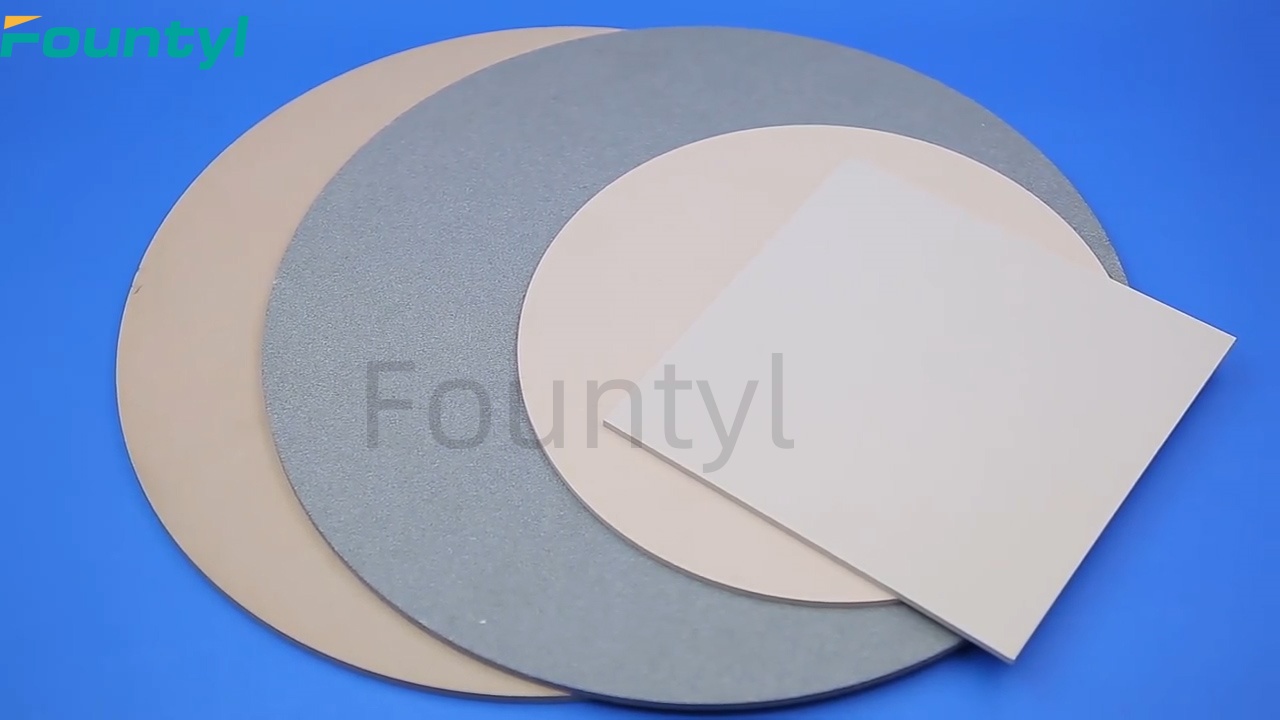

Porous yumbura tare da babban porosity suna da kyau, amma mafi girma da porosity, ƙananan ƙarfin abu. Bugu da ƙari, lokacin da ƙarancin ƙura ya yi ƙasa, porosity ya zama ƙasa ko girman pore ya zama mafi girma a daidai wannan porosity. Sabili da haka, kayan da ke da ƙananan ƙarancin pore kuma suna da ƙananan ƙarfi. Tukwalwar tukwane tukwane tare da pores da yawa a cikin kayan, waɗanda ake amfani da su don masu tsotsa ta hanyar fasahar sintering yumbu.

Porous yumbu chuck ne kuma daya daga cikin manyan kayayyakin na Singapore Fountyl Technologies PTE Ltd., R&D da kuma samar da irin wannan samfurin fiye da shekaru 10, babban abu ne porous tukwane, babban aka gyara na kayan ne alumina da silicon carbide. amfani da siliki wafers, semiconductor fili wafers, gilashin, piezoelectric yumbu, LED, semiconductor marufi bangaren substrate, Tantancewar bangaren thinning, yankan filayen.

Gida

Gida