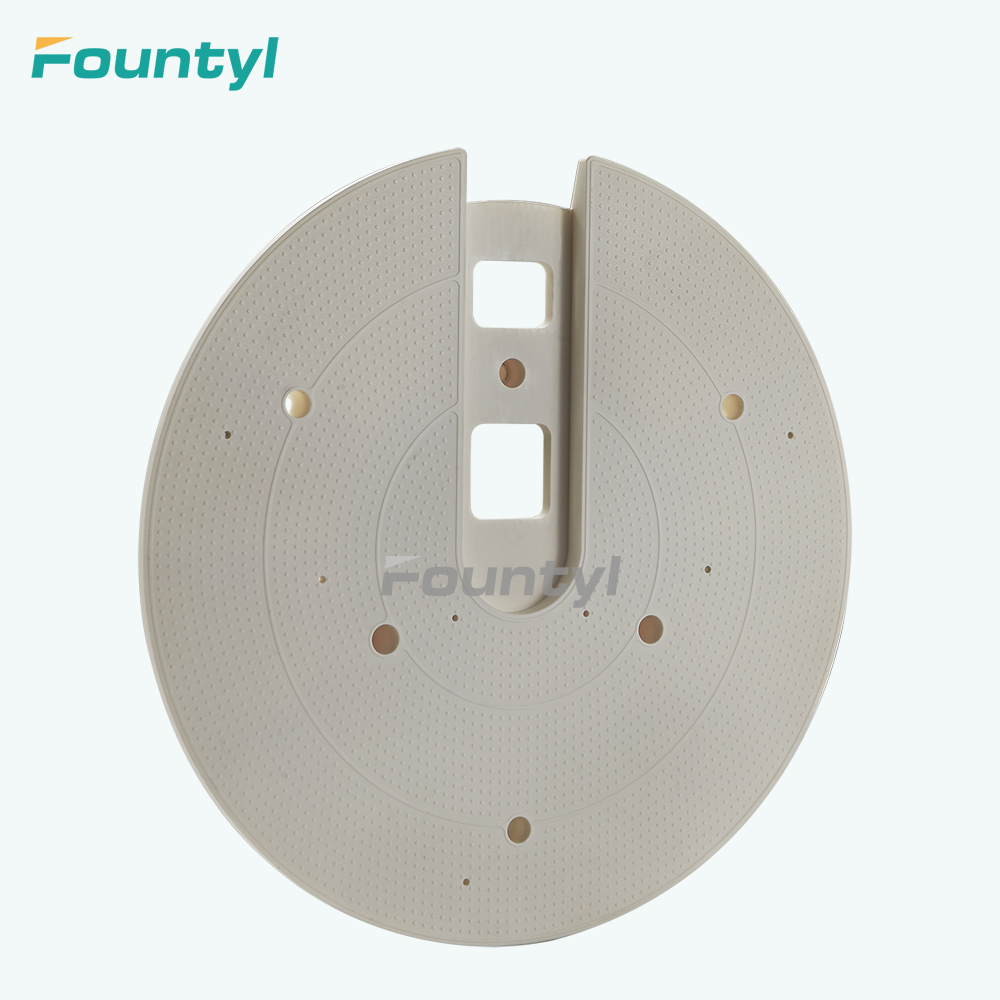

Wafer fil chuck da aka yi amfani da shi don na'urar bayyanar semiconductor da na'urar duba wafer

Siffofin

Babban juriya na zafin jiki:Silicon carbide da kayan yumbu na alumina suna da kyakkyawan aikin zafin jiki, ana iya amfani da su a cikin yanayin zafin jiki na dogon lokaci, ba sauƙin lalacewa ko fashewa ba.

Juriya na lalata:zai iya jure nau'in lalatar sinadarai, wanda ya dace da sarrafa gurɓataccen ruwa ko iskar gas a cikin yanayin aiki.

Saka juriya:babban taurin, tare da juriya mai kyau, ana iya amfani dashi na dogon lokaci ba tare da gazawa ba.

Ƙarfafawa mai ƙarfi:da convex batu tsarin rage lamba yankin na tsotsa kofin, game da shi yana ƙara adsorption ƙarfi da naúrar yankin, kuma zai iya da tabbaci adsorb da workpiece.

Babban kwanciyar hankali:Saboda halaye na kayan, wafer fil chuck yana da babban kwanciyar hankali kuma yana iya aiki a tsaye na dogon lokaci.

Rage gurbatar yanayi:Yumbun wafer chucks suna tasowa daga tsagi zuwa fil don rage wurin hulɗa, rage wasu gurɓataccen gurɓataccen yanayi da haɓaka gyaran gyare-gyare.

Sarrafa tsari

Babban madaidaici: 12 inci diamita, ana sarrafa flatness a cikin 5 μm; Idan kuna buƙatar ƙarin daidaito, da fatan za a yi mana imel.

Sarrafa siffar: Daidaita siffar chuck bisa ga siffar wafer (ikon rashin daidaituwa).

Amsa mai ɗaukar nauyi: ƙira na musamman bisa ga ƙayyadaddun bayanai.

Ayyukanmu

Ya kamata a yi la'akari da zaɓin wafer fil chuck bisa ga dalilai masu yawa kamar diamita da ake buƙata na kofuna na tsotsa, adadin ma'auni na convex, da siffar chuck, da kuma yin zabi mai dacewa bisa ga girman, nauyin adsorption. abu da bukatun yanayin aiki.

Mun rungumi madaidaicin fasahar injin lebur, aiwatar da ƙira don al'ada, da kuma samar da mafi kyawun walƙiya fil don saduwa da ƙayyadaddun buƙatun abokan ciniki.

Za'a iya daidaita siffa mai lebur ɗin fil ɗin cikin yardar kaina bisa ga sifar wafer, kuma yankin talla ko ƙirar fil za a iya keɓancewa don haɓaka amsawar talla.

Abu: Aluminum oxide yumbu ko silicon carbide za a iya zaba, da kuma DLC da Teflon za a iya plated a saman.

Ana haɓaka madaidaicin SiC/SSiC wafer fil chucks don faɗuwar wafer, dubawa, hanyoyin sufuri waɗanda ke da sassauƙa sosai, lebur sosai, da juriya sosai ga yanayin aiki mai tsauri.

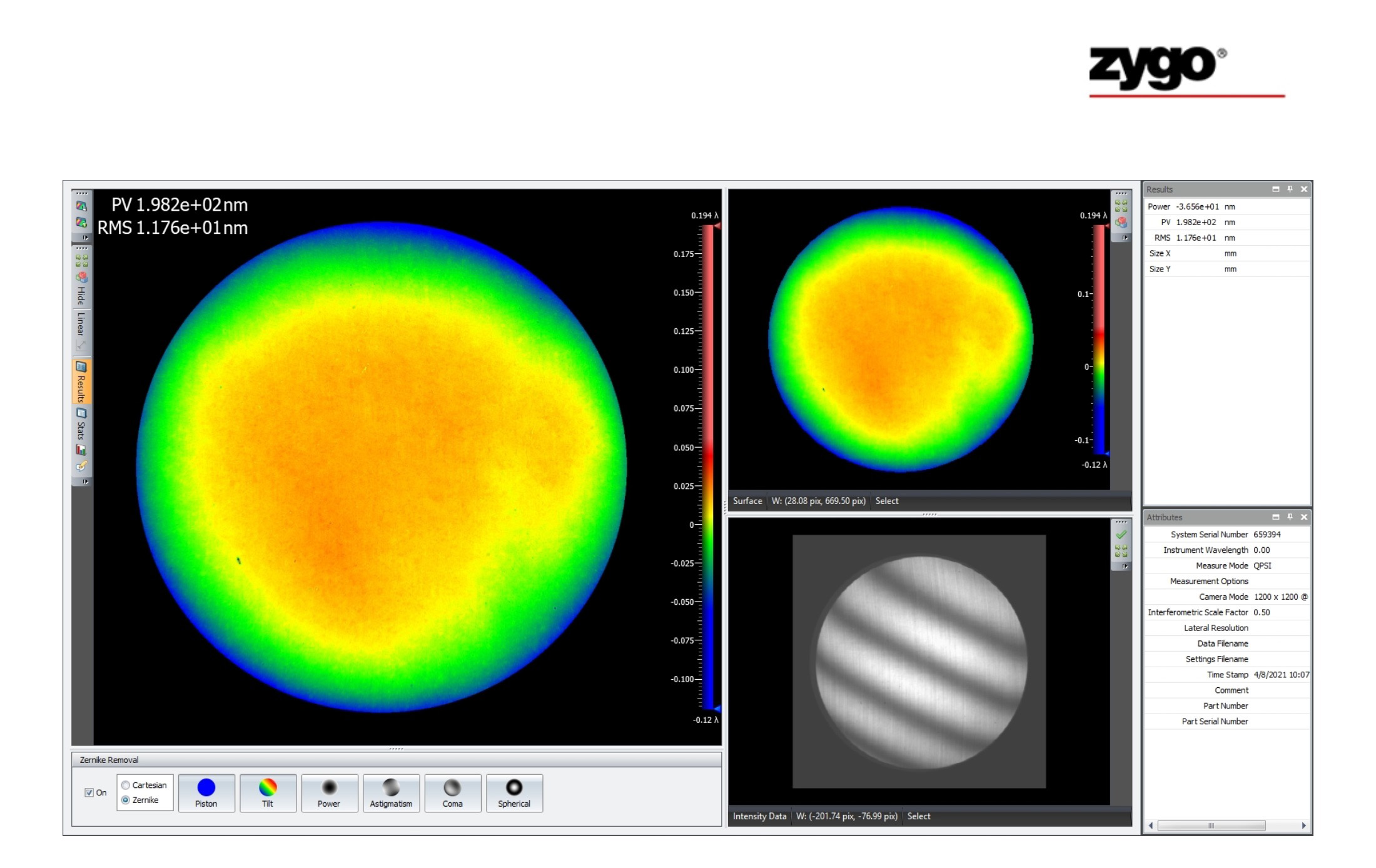

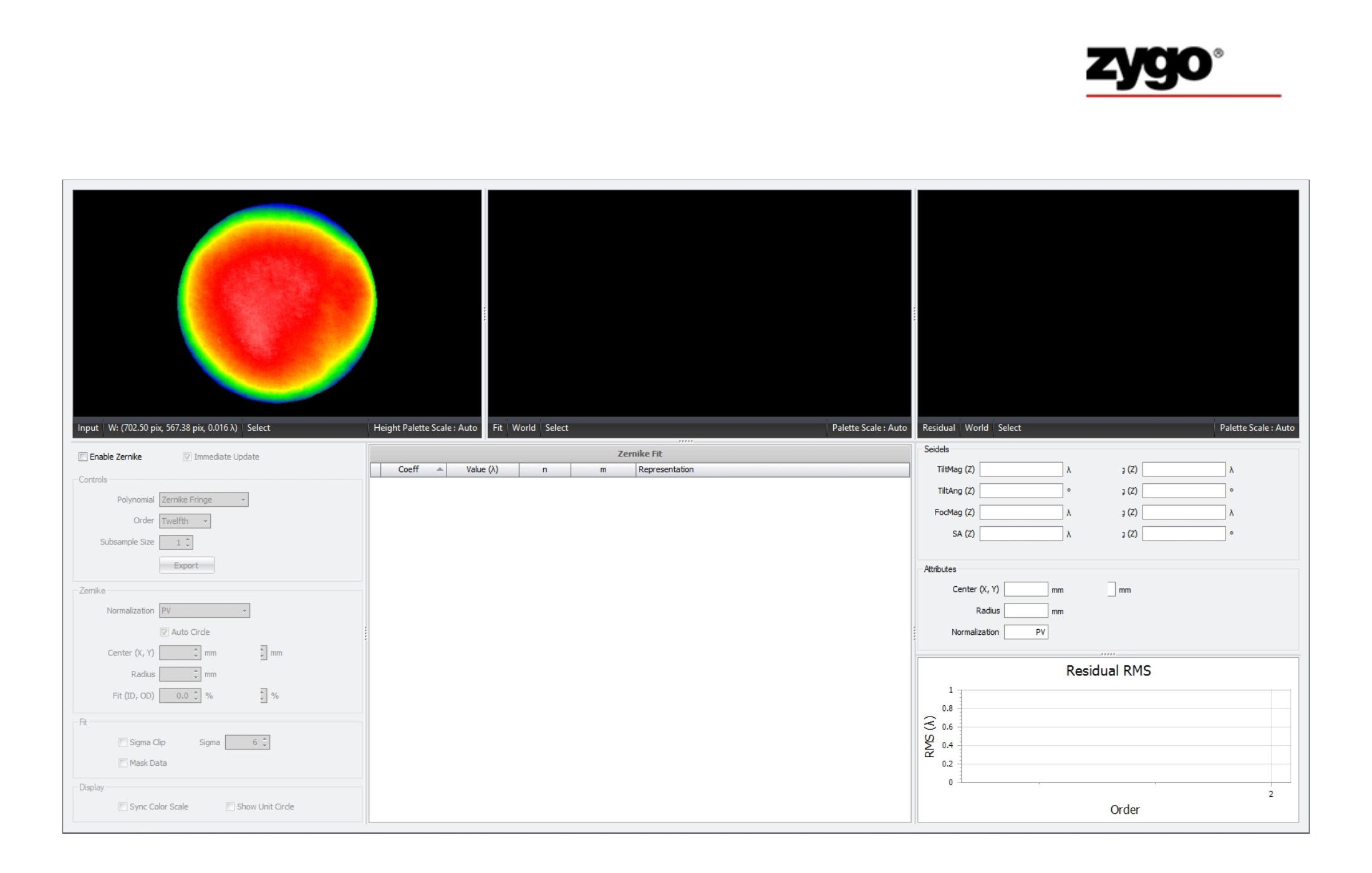

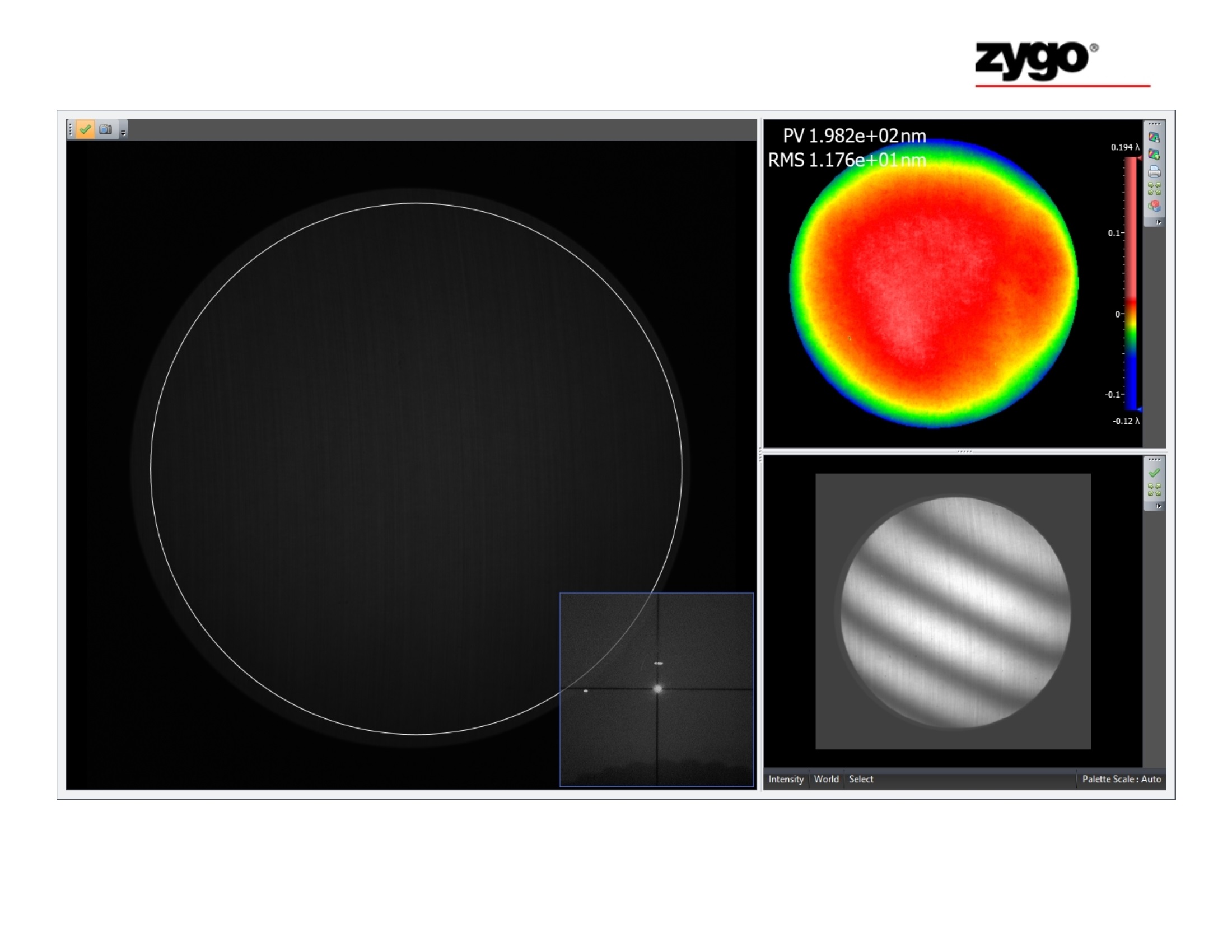

Daidaiton Bayanan Gwajin

Aikace-aikace

Wafer gyaran gyare-gyare na na'urar bayyanar semiconductor; Gyaran wafer na na'urar duba wafer.

Gida

Gida