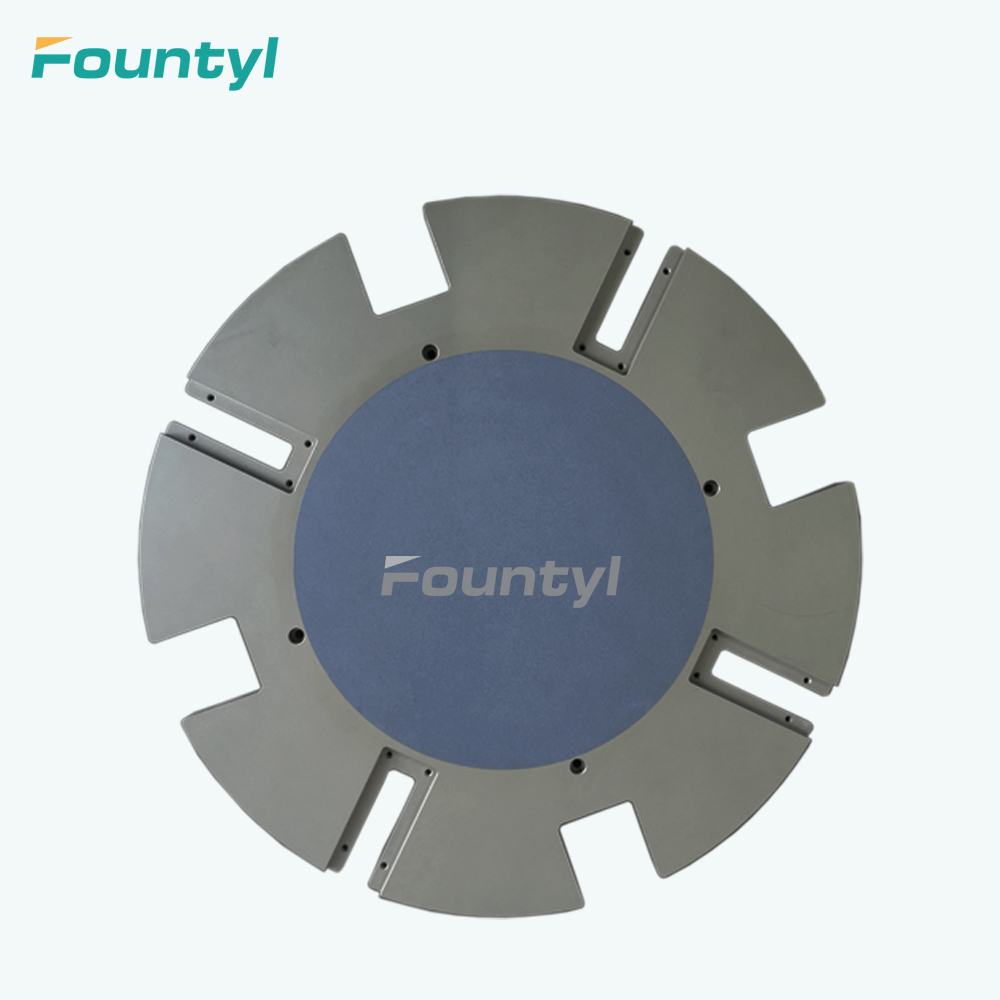

Microporous Ceramic Nqus Chuck

Ceramic nqus chuck feature

Muaj zog permeability: uniform huab cua permeability thiab dej permeability, los xyuas kom meej lub uniform quab yuam thiab nruj adsorption ntawm silicon wafer nyob rau hauv cov txheej txheem sib tsoo yam tsis muaj swb.

Ntev thiab cov qauv coj mus los: kev saws me me ntawm cov khoom siv ntom ntom ntom thiab cov qauv tsis yooj yim, thiab lub chuck yooj yim kom ntxuav.

Lub zog siab: tsis muaj deformation thaum sib tsoo, kom ntseeg tau tias cov silicon wafer sib npaug ntawm txhua qhov taw tes thaum sib tsoo, thiab nws tsis yooj yim rau qhov tshwm sim ntawm ntug vau, khib nyiab.

Lub neej ntev: lub ntsej muag zoo tuav tau zoo, lub voj voog hnav khaub ncaws ntev thiab hnav khaub ncaws me me, yog li nws muaj lub neej siab.

Kev hnav khaub ncaws yooj yim: yuav tsis muaj qhov tawg, tawg, threshing tshwm sim thaum hnav khaub ncaws.

Lub teeb yuag: Vim yog cov qauv sab hauv ntawm qhov pores, qhov tshwj xeeb lub ntiajteb txawj nqus coefficient yog 1.6-2.8.

High rwb thaiv tsev: cov khoom siv insulating, tshem tawm hluav taws xob zoo li qub.

Tswj qhov tseeb

| qeb | Cov khoom siv hauv paus | Adsorption nto khoom | Loj | Flatness | qhov tob ntawm parallelism |

| Porous chuck | Aluminium Alloy | Porous SIC | ≤12μm | ≤15μm | ≤ 20μm |

| Stainless hlau | ≤10μm | ≤15μm | |||

| Alumina | ≤ 5μm | ≤ 8m | |||

| Silicon Carbide | ≤ 3μm | ≤ 8m | |||

| Cov porous ceramic chuck muaj ntau yam kev qhia tshwj xeeb thiab ntau thiab tsawg, uas tuaj yeem siv rau hauv kab 3-nti, 4-nti kab, 5-nti kab, 6-nti kab, 8-nti kab thiab 12-nti kab, thiab tuaj yeem kho raws li qhov tshwj xeeb thiab qhov ntau thiab tsawg koj xav tau. | |||||

| Qhov siab tshaj plaws ntawm cov ntaub ntawv tam sim no yog: 1600 * 1600m, thickness yog 50mm; | |||||

Porous ceramic khoom yam ntxwv:

Cov khoom xyaw tseem ceeb: alumina Xim: dub, hlau grey

Alumina cov ntsiab lus: 92% Moisture content: 0%

Aperture: 2 ~ 30um Porosity: 35 ~ 40%

Bending zog: 6kgf / cm2 (Mpa) Volume ratio: 2.28g / cm3

Ceramic chuck hom

Raws li kev siv, Ceramic chuck tau muab faib ua:

Thinning tshuab nruab nrog: abrasive disc chuck, silicon wafer, sapphire substrate thiab lwm yam thinning;

Lub tshuab txiav yog nruab nrog: scribing chuck, silicon wafer, semiconductor compound wafer thiab lwm yam txiav;

Ntxuav lub tshuab nruab nrog: tu chuck;

Zaj duab xis tshem tshuab yog nruab nrog: zaj duab xis tshem chuck;

Laminating tshuab nruab nrog: laminating chuck;

Lub tshuab luam ntawv nruab nrog: luam ntawv chuck.

Kev ruaj ntseg zoo

Fountyl muaj ntau xyoo ntawm kev paub txog engineering ceramic precision thiab ultra-precision ua thiab kev tsim khoom, ntau yam kev ntsuas lub cev thiab tshuaj lom neeg thiab cov ntsuas ntsuas geometric, kom ntseeg tau tias kev ruaj khov ntawm kev tsim khoom thiab sib xws ntawm cov khoom rau cov khoom siv ceramic chuck.

Khoom siv

Porous chuck (adsorption ua hauj lwm rooj) yog ib feem siv nyob rau hauv lub semiconductor manufacturing theem thiab sib sau ua ke ntawm lub tshuab scribing los yog tshuaj ntsuam xyuas. Nws yog ib yam khoom uas tuaj yeem siv cov qauv ntxeem tau thiab qhov tsis zoo ntawm qhov chaw ntawm lub workbench kom nyias nyias silicon wafer tiaj tus. Lub tshuab scribing txiav cov silicon wafer nrog qhov dav txog 20μm, yog li qhov yuav tsum tau ua rau flatness thiab parallelism ntawm wafer adsorption nto yog siab heev. Raws li lawv cov yam ntxwv, cov qauv pore sib txawv muaj cov ntawv thov sib txawv, xws li microporous ceramics nrog thaj tsam loj thiab qhov pore me me, feem ntau yog siv hauv cov kab mob pom thiab microbial fixation teb; Mesoporous ceramics nrog lawv cov kab sib txawv tshwj xeeb feem ntau siv hauv kev sib cais, adsorption catalysis teb. Macroporous ceramics feem ntau yog tsim rau kev lim dej ntxhib ntawm cov khoom uas muaj cov ntsiab lus loj thiab loj loj.

Tsev

Tsev