Demand and application of alumina powder in electronic manufacturing, semiconductor, new energy and other high-end fields

Fine alumina powder through the precision processing of industrial raw materials to adapt to the application needs of different industries, mainly industrial alumina as raw materials, through purification, calcination, grinding, homogenization, grading and other processing processes, control powder crystal morphology, crystal phase conversion, particle size and distribution, sensitive specific elements, surface properties and activity and other technical indicators. It has the characteristics of insulation, high temperature resistance, high thermal conductivity and stable chemical properties, which can meet the specific material application needs of different downstream fields. At present, the application of fine alumina powder as an electronic material has received more and more attention, and it is an important basic material for the production of electronic ceramic devices, electronic glass, lithium battery separator, high voltage electrical appliances, wafer grinding and polishing materials, etc. Terminal applications cover integrated circuits, consumer electronics, power engineering, electronic communications, new energy vehicles, flat panel display, photovoltaic power generation and other key areas vigorously developed by many countries.

1, Electronic ceramics field

Electronic ceramics refers to the ceramic materials used in the electronic industry to prepare various electronic components, mainly with inorganic non-metallic materials such as oxides or nitride powders as the main components for sintering, through structural design, accurate stoichiometry, appropriate forming methods and firing systems. So that it has high mechanical strength, high insulation resistance, high temperature and humidity resistance, radiation resistance, capacitance change rate can be adjusted and other excellent characteristics. Among them, fine alumina is one of the main materials for the production of electronic ceramic substrates, ceramic packaging materials, electric vacuum tube shells, HTCC ceramics and other electronic ceramic components, and is also an auxiliary material for the production of MLCC and other ceramic products.

2, Electronic glass field

Electronic glass can be divided into display glass substrate and cover glass. The display glass substrate is an important part of the display panel (mainly TFT-LCD and OLED) in the electronic equipment such as mobile phone and TV, which has a direct and significant impact on the performance of the panel. The cover glass is located above the display panel, which plays a supporting and protective role, and ensures that it can maintain a good display effect when it is impacted or scratched. At present, the display panel industry has gradually expanded from traditional fields such as computers and mobile phones to application fields such as vehicle display and smart wearable devices, and the industry has ushered in new development opportunities.

3, Power transmission and transformation

Power transmission and transformation refers to the power transmission process from the power plant to the grid through the way of first rise and then fall, divided into high-voltage transmission and transformation, high-voltage transmission is a power plant through the transformer output voltage of the generator after transmission, substation is to meet the safety needs, and reduce the voltage, distributed to each user. With the support of a series of national power grid construction policies, the steady growth of power grid investment has driven the sustainable development of the power transmission and transformation industry, and the market size of high voltage appliances and UHV appliances is expected to continue to expand.

4, Lithium battery diaphragm coating field

Fine alumina is the key material for membrane coating of lithium battery. Coating on one or both sides of the membrane surface can significantly improve the high temperature stability and alleviate the safety problems of battery contact, combustion and explosion caused by the thermal contraction of the membrane. After coating, the membrane thickness increases, and the stability and life of the membrane are significantly improved. In terms of coating technology, coating materials mainly include inorganic coating, organic coating and functional multilayer coating. Compared with organic coating and functional multi-layer coating technology, inorganic coated diaphragm has better tensile strength and thermal shrinkage, and the technology is more mature, and downstream customers have formed industrial applications.

5, Field of thermal conductive filler

With the development of electronic components to stacked and integrated, the market puts forward higher requirements for the heat dissipation of thermal conductive filling materials. The downstream of spherical alumina is mainly used for the production of thermal interface materials (such as thermal gaskets, thermal silicon grease, thermal potting-sealing glue, etc.), thermal engineering plastics, thermal aluminum-based copper clad plates, special ceramics, etc., and can eventually be extended to new energy, electronic materials, high-end substrate industry packaging.

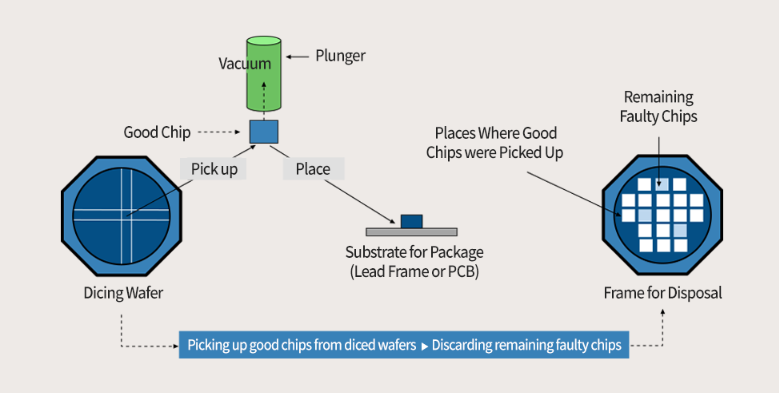

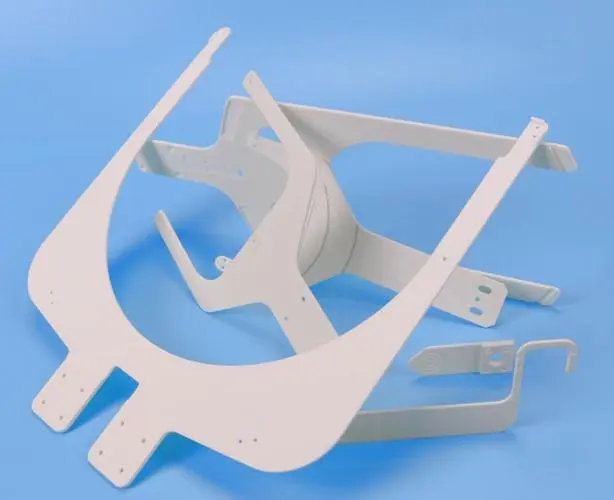

6, Semiconductor ceramic parts field

Ceramic has high hardness, high elastic modulus, high wear resistance, high insulation, corrosion resistance, low expansion and other advantages, can be used as silicon polishing machine, epitaxial/oxidation/diffusion and other heat treatment equipment, lithography machine, deposition equipment, semiconductor etching equipment, ion implantation machine and other equipment parts, so the research and development of precision ceramic parts directly affect the development of semiconductor industry. The technical requirements of its preparation are getting higher and higher. Usually semiconductor equipment ceramic alumina, silicon nitride, aluminum nitride, silicon carbide, etc., among them, alumina as the "most cost-effective" precision ceramic material, has a very common application in this field.

7, Grinding and polishing field

As one of the most widely used polishing powder, alumina polishing powder cutting rate, good light effect, simple production process, low cost advantages, suitable for a variety of materials surface processing, including metal, plastic, ceramics, etc., in electronics, optics, aerospace and other fields widely used. Especially in the current semiconductor field of wafer CMP polishing, alumina plays an important role in the precision polishing process of wafer.

Fountyl Technologies PTE Ltd, is focusing on semiconductor manufacturing industry, main products include: Pin chuck, porous ceramic chuck, ceramic end effector, ceramic square beam, ceramic spindle, welcome to contact and negotiation!