Silicon carbide ceramics used in semiconductor/integrated circuit manufacturing equipment

Silicon carbide ceramics play an important role in semiconductor/integrated circuit manufacturing equipment due to their unique physical and chemical properties. However, it should be noted that at present, the research and development and application of precision ceramic structural parts for integrated circuit core equipment are mainly concentrated in the United States, Japan, Europe and other places, and they are still in an absolute monopoly position. Therefore, China still needs further research and breakthrough in silicon carbide ceramic materials and related preparation technology.

1, Grinding and polishing chuck

In the production process of silicon carbide polishing chuck, silicon carbide ceramic material is processed into the shape of the chuck, and through special process treatment, so that its surface has excellent grinding and polishing properties. When used, the chuck grinds and polishes the surface of the workpiece by absorbing the surface of the workpiece, using the hardness and sharpness of silicon carbide ceramics to remove impurities such as burrs and oxides on the surface, and improve the finish and accuracy of the surface of the workpiece.

The main features of silicon carbide grinding and polishing chuck include:

o High hardness: silicon carbide ceramics have extremely high hardness, second only to diamond, so they can effectively carry out grinding and polishing operations to remove defects and irregularities on the surface of the material.

o High wear resistance: The high hardness of silicon carbide ceramics also brings good wear resistance, which can maintain small wear during the long grinding and polishing process and improve the service life of the tool.

o High thermal stability: Silicon carbide ceramics have high thermal stability and low coefficient of thermal expansion, can maintain stable performance in high temperature environment, suitable for high temperature grinding and polishing operations.

o Good chemical stability: silicon carbide ceramics have good stability to most chemical substances, are not easy to be corroded and eroded, and can maintain stable performance in a variety of environments.

2, Lithographic chuck

Silicon carbide lithography chuck plays an important role in the manufacturing process of integrated circuits. It can provide stable and high-precision silicon wafer fixation and support to ensure the smooth progress of the lithography process, thereby improving the manufacturing efficiency and quality of integrated circuits.

It should be noted that silicon carbide lithography chuck is a key component in integrated circuit manufacturing, and its manufacturing technology and precision requirements are very high. At present, only a few foreign companies can manufacture lithographic chuck to meet the requirements of integrated circuit manufacturing, and China's technology and products in this area need to be further developed and improved.

The main features of silicon carbide lithography chuck include:

o high precision: Silicon carbide ceramics have extremely high hardness and accuracy, which can meet the high precision fixation and support requirements of silicon wafers in the integrated circuit manufacturing process.

o High stability: Silicon carbide ceramics have high thermal stability and low thermal expansion coefficient, which can maintain a stable size and shape during the lithography process to avoid affecting the lithography accuracy.

o Good chemical stability: silicon carbide ceramics have good stability to most chemical substances, are not easy to be corroded and eroded, and can maintain stable performance during the lithography process.

o High adsorption force: Silicon carbide lithography sucker adopts special adsorption technology, which can firmly adsorb silicon wafers to ensure that it will not shift or shake during the lithography process, ensuring the accuracy and stability of lithography.

3, Detection chuck

silicon carbide detection chuck can ensure the smooth progress of the detection process, thus improving the manufacturing quality of integrated circuits. At the same time, the service life of silicon carbide detection chuck is long, which can reduce manufacturing costs and maintenance costs, and improve the overall economic benefits.

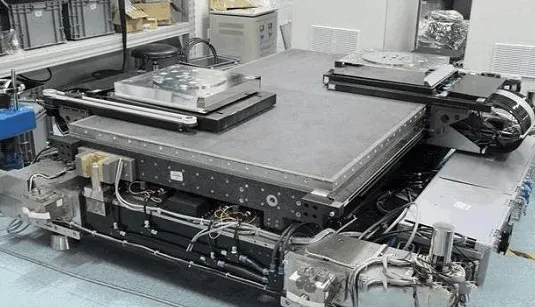

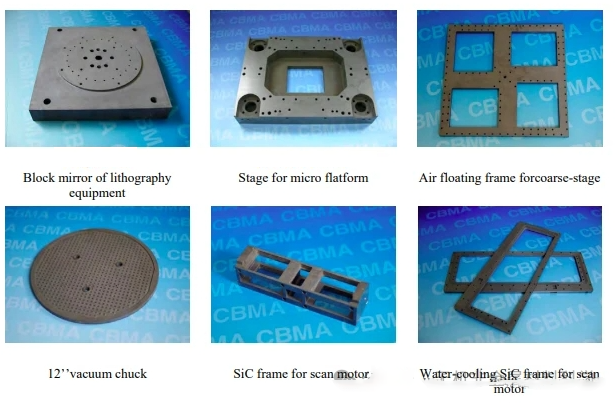

4, Precision motion platform

Silicon carbide precision motion platform plays an important role in various high-precision manufacturing and processing fields. It can provide high-precision and high-stability motion control solutions for semiconductor processing, optical manufacturing, nanotechnology and other fields to improve product quality and production efficiency.

The main features of silicon carbide precision movement platform include:

o High precision: silicon carbide ceramics have extremely high hardness and accuracy, which can meet the high precision requirements of the movement platform and ensure the stability and accuracy of the platform during the movement.

o High stability: Silicon carbide ceramics have high thermal stability and low thermal expansion coefficient, which can maintain stable performance in high temperature and harsh environment, reduce dimensional deformation and thermal error, and ensure the long-term stability of the platform.

o Lightweight: Silicon carbide ceramics have low density and high strength, which can realize the lightweight design of the platform, reduce the movement inertia, reduce the motor load, and improve the dynamic response and acceleration of the platform.

o High wear resistance: Silicon carbide ceramics have excellent wear resistance, can resist high-speed movement and heavy load wear, extend the service life of the platform.

5, High purity silicon carbide parts for etching links

In the etching process, high-purity silicon carbide components play a key role. High purity silicon carbide has excellent physical and chemical properties, such as high hardness, high thermal stability, good chemical stability, and low reactivity, which makes it an ideal material for etching equipment.

high purity silicon carbide parts play a key role. High purity silicon carbide has excellent physical and chemical properties, such as high hardness, high thermal stability, good chemical stability, and low reactivity, which makes it an ideal material for etching equipment.

In plasma etching equipment, high-purity silicon carbide is often used to manufacture key components such as focusing rings, gas spray heads, pallets, edge rings, etched cavities, etched gas nozzles, etc. These components play a vital role in the etching process, such as the focusing ring to ensure the uniform distribution of plasma, the gas spray head to precisely control the gas injection, the tray and edge ring to support and stabilize the wafer to be etched.

High purity silicon carbide parts show good stability in the environment containing chlorine and fluorine etching gas, and its low reactivity can effectively reduce the corrosion and damage to the equipment during the etching process. In addition, high-purity silicon carbide also has a similar electrical conductivity to silicon, which enables it to effectively conduct current during the etching process, ensuring the uniformity and consistency of the etching.

With the continuous progress of integrated circuit manufacturing, the requirements for etching technology are becoming higher and higher. High-purity silicon carbide components, with their excellent performance and stability, are one of the keys to meeting these requirements. With the continuous development of technology, the application of high-purity silicon carbide in the etching process will be more and more extensive.

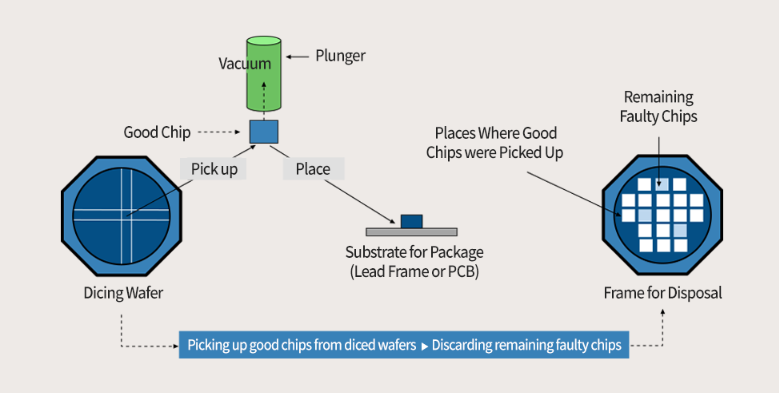

6, Precision motion system in package inspection

In the high-speed and high-precision motion control, the high hardness and low friction of silicon carbide ceramics can reduce wear and friction, and improve the stability and life of the system. At the same time, in the process of package inspection, the temperature change may have an impact on the precision motion system, and the application of silicon carbide ceramics can effectively reduce this impact and improve the reliability and stability of the system.

The precision motion system of silicon carbide ceramics in the packaging and testing link includes the key components such as guide rail, bearing and slide block. The manufacturing accuracy and performance of these components directly affect the stability and accuracy of the entire motion system. Therefore, the high-precision processing technology and surface treatment technology of silicon carbide ceramics are also crucial.

Silicon carbide ceramics are also used for precision motion systems in the manufacturing package inspection process, such as alignment and fitting during chip packaging.

Silicon carbide ceramics play an important role in the precision motion system of package inspection. With the continuous progress of technology and the expansion of application fields, the application of silicon carbide ceramics in precision motion systems will be more and more extensive.

FOUNTYL TECHNOLOGIES PTE. LTD. is a modern enterprise in the field of advanced ceramics set R&D, manufacturing and sales as one, mainly produces porous ceramics, alumina, zirconia, silicon nitride, silicon carbide, aluminum nitride, microwave dielectric ceramics and other advanced ceramic materials. our specially invited Japanese technology expert have more than 30 years of industry experience in semiconductor field, efficiently provide special ceramic application solutions with wear resistance, corrosion resistance, high temperature resistance, high thermal conductivity, insulation for domestic and foreign customers.