Mawonekedwe

Kugwirizana | Kusintha mwamakonda | Kuchuluka Kwambiri | Mphamvu Zazikulu Zazikulu | Nthawi Yotumizira Mwachangu | Zotsika mtengo

Mapulogalamu

Lon-implantation | Kanema Woonda | Eti | Kukula kwa Njira | Zida Zopangira

Kupanga ndi Kupanga

12 inch Fab yoperekedwa kuti itsimikizire momwe ikugwirira ntchito, kupereka kukonzanso ndi kukonza, ndikutsimikizira chitukuko ndi mapangidwe.

Ndi zida ndondomeko ndi ndondomeko luso chitukuko cha semiconductor ndi dera Integrated, miyambo electrostatic chucks ntchito organic polima zipangizo, oxides zitsulo ndi zipangizo ceramic monga dielectrics si mokwanira n'zogwirizana ndi zipangizo monga pakachitsulo yopyapyala, safiro ndi pakachitsulo carbide. Choncho, chucks electrostatic n'zogwirizana ndi woyamba, wachiwiri ndi wachitatu m'badwo semiconductor yopyapyala grippers adzakhala pang'onopang'ono kukhala.

Polima Electrostatic Chuck / Heater

Polima dielectric chuma (Polymer) pakali pano amagwiritsidwa ntchito kwambiri electrostatic chuck zakuthupi, kukonzekera kwake ndi okhwima kwambiri, polima dielectric zinthu pambuyo polima kusinthidwa mankhwala, magetsi, makina, kutentha kukana, halogen kukana katundu adzakhala bwino kwambiri. Zinthu za dielectric zimatengera magwiridwe antchito ena ophatikizika, kenako ndikuwunjika ndi multistage vacuum heavy load, ndipo wosanjikiza wandiweyani wa dielectric insulation umapangidwa pakati pa maelekitirodi amkati.

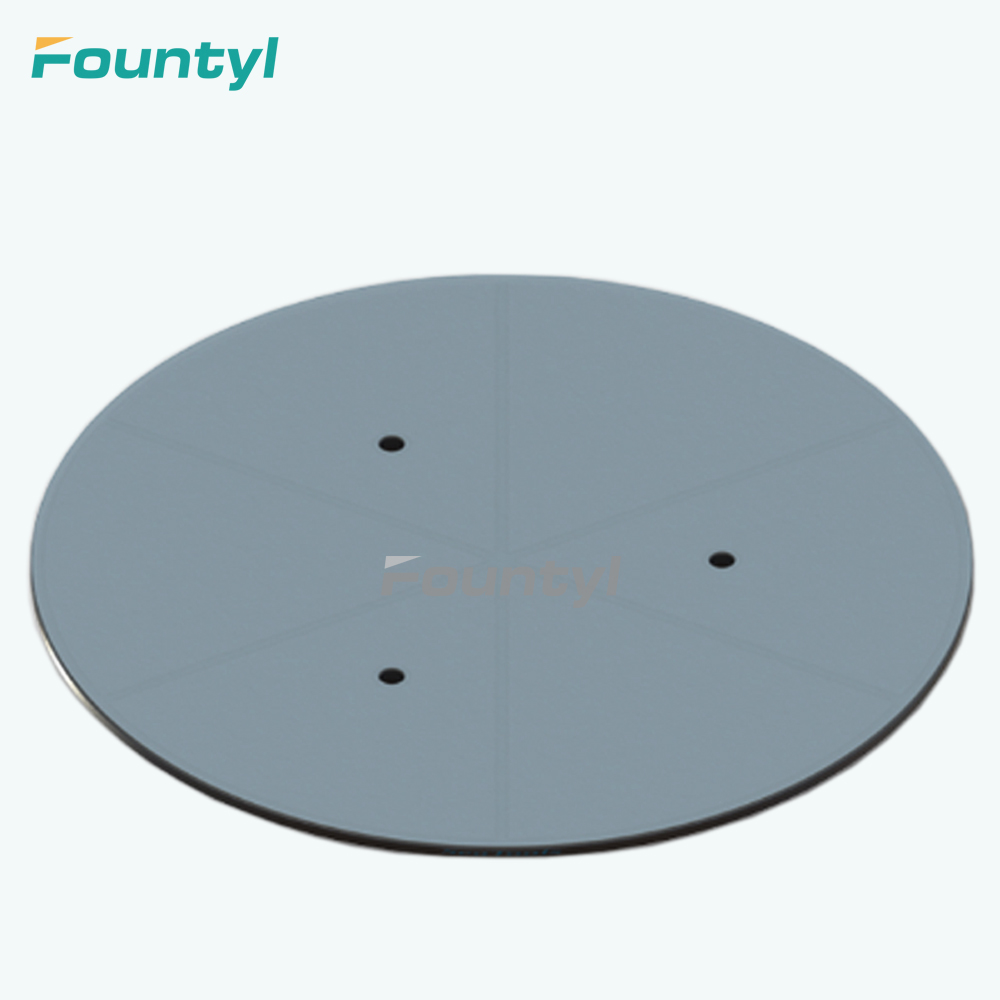

Polymer Electrostatic Chuck

Ukadaulo wosintha ma polima umagwiritsidwa ntchito kuti akwaniritse zochulukirapo zochulukirapo komanso kusinthasintha kwa dielectric, ndikupeza mphamvu yolimba yolimba.

Zida za dielectric zamphamvu kwambiri zimatha kuchepetsa chiwopsezo cha tinthu tating'onoting'ono ndikuchepetsa kuyenda kwa ion.

Kusiyanasiyana kwa zinthu zokhotakhota kumatha kukhala kogwirizana ndi kumangirira kwa ma wafer azinthu zosiyanasiyana.

Kukana kwabwino kwa dzimbiri mu halogen ndi plasma atmospheres.

Kugwira ntchito kwamtengo wapatali, nthawi yochepa yovomerezeka, yoyenera pa chitukuko cha ndondomeko ya mankhwala ndi chitsimikizo cha chitukuko cha zida zatsopano.

Al₂O₃ Electrostatic Chuck

Voliyumu resistivity imayendetsedwa ndi ukadaulo wa coagulation ceramic komanso njira yowombera kuti mupeze mphamvu yayitali.

Mapangidwe amkati a kutentha kwa sintering ndi wandiweyani ndipo mawonekedwe a kristalo ndi okhazikika, ndipo mphamvu yogwiritsira ntchito kutentha kwakukulu imatha kupezeka.

Kuwotcha kophatikizana kophatikizana kumachepetsa kusamuka kwa ion.

Ntchito yokhalitsa mu plasma halogen vacuum atmosphere.

Kunyumba

Kunyumba