Features

Kugarisana | Customization | High-Density | High Structural Strength | Yekukurumidza Yekutumira Nguva | Mari-inoshanda

Applications

Lon-implantation | Thin Film | Etch | Process Development | Equipment Design

Dhizaini uye Kugadzira

12 inch Fab inounzwa kuti ione kuita chaiko, kupa kuvandudzwa uye kugadzirisa, uye kuona budiriro uye dhizaini.

Iine michina yekugadzira uye process tekinoroji kusimudzira semiconductor uye yakabatanidzwa dunhu, iyo yechinyakare electrostatic chucks inoshandisa organic polymer zvinhu, simbi oxides uye ceramic zvinhu se dielectrics hazvienderane zvizere nezvinhu zvakadai sesilicon wafers, safiro uye silicon carbide. Naizvozvo, electrostatic chucks inoenderana neyekutanga, yechipiri uye yechitatu chizvarwa semiconductor wafer grippers inokura zvishoma nezvishoma.

Polymer Electrostatic Chuck / Heater

Polymer dielectric zvinhu (Polymer) parizvino ndiyo inonyanya kushandiswa electrostatic chuck zvinhu, maitiro ayo ekugadzirisa zvakare akanyanya kukura, polymer dielectric zvinhu mushure mekugadziriswa kwepolymer kurapwa, magetsi, mechanic, kuramba tembiricha, halogen kuramba zvivakwa zvichavandudzwa zvakanyanya. Iyo dielectric zvinhu inofananidzwa nemamwe mashandisirwo akabatanidzwa, uyezve akaturikidzana neakawanda nhanho vacuum inorema mutoro, uye dense dielectric insulation layer inoumbwa pakati pemagetsi emukati.

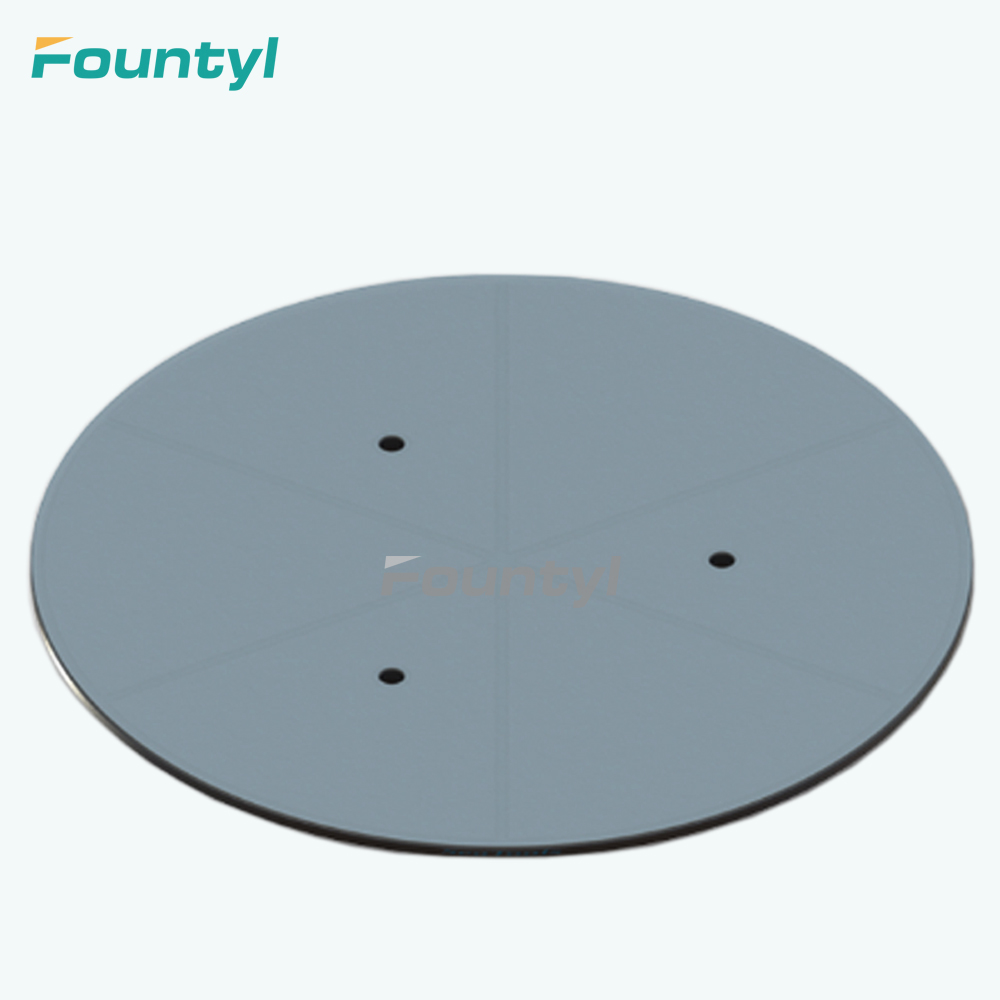

Polymer Electrostatic Chuck

Iyo polymer shanduko tekinoroji inoshandiswa kuwana yakakwira yakawanda resistivity uye hama dielectric nguva dzose, uye kuwana yakawedzera kugadzikana clamping simba.

Yakakwira density dielectric zvinhu zvinogona kuderedza njodzi yechinhu chechikamu uye kuderedza ion kufamba.

Kusiyana kwezvinhu zvinosungirirana zvinogona kuenderana nekusungirirwa kwewafers emhando dzakasiyana.

Yakanakisa corrosion kuramba mu halogen uye plasma atmospheres.

Kushanda kwemutengo wepamusoro, nguva pfupi yekugamuchirwa, yakakodzera kugadzirwa kwechigadzirwa uye kusimbiswa kwemidziyo mitsva.

Al₂O₃ Electrostatic Chuck

Iyo vhoriyamu resistivity inodzorwa necoagulation ceramic tekinoroji uye co-firing process kuti iwane refu kubata simba.

Iyo yemukati chimiro chepamusoro tembiricha sintering yakaomeswa uye chimiro chekristaro chakagadzikana, uye simba rekubata reiyo tembiricha yakakura inogona kuwanikwa.

Integrated co-firing molding inoderedza ion migration.

Kushanda kwenguva refu muplasma halogen vacuum atmosphere.

Kumba

Kumba