0102030405

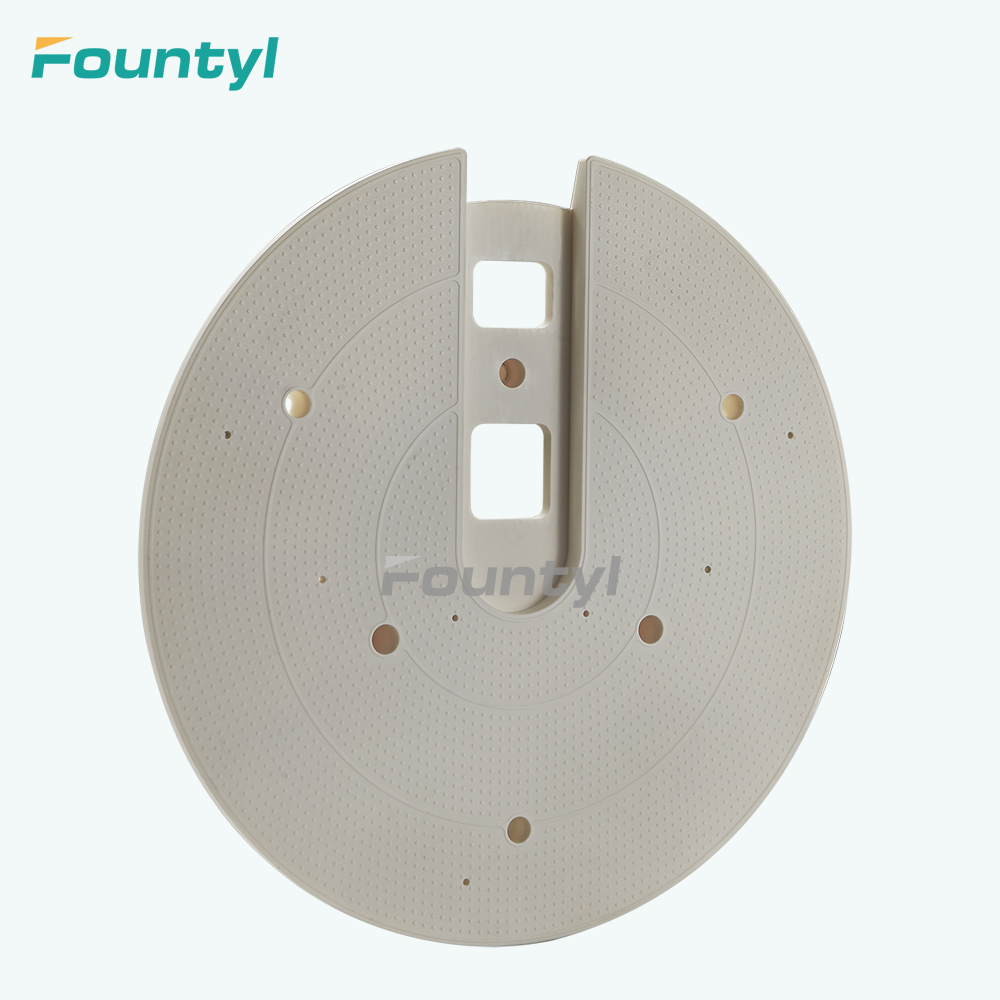

Wafer pini chuck inoshandiswa semiconductor exposure mudziyo uye wafer yekuongorora mudziyo

Features

High tembiricha kuramba:Silicon carbide uye alumina ceramic zvinhu zvine yakanakisa tembiricha yekuita, inogona kushandiswa munzvimbo yekushisa yakakwira kwenguva yakareba, zvisiri nyore kushandura kana kutsemuka.

Corrosion resistance:inogona kumira zvakasiyana-siyana zvemakemikari corrosion, akakodzera kubata zvinwiwa zvinopisa kana magasi munzvimbo yekushanda.

Kuramba kupfeka:kuoma kwepamusoro, nekunaka kupfeka kusagadzikana, kunogona kushandiswa kwenguva yakareba pasina kukundikana.

Yakasimba adsorption:iyo convex point chimiro inoderedza nzvimbo yekubata yekapu yekuyamwa, nekudaro ichiwedzera adsorption simba pane imwe unit nzvimbo, uye inogona zvakanyanya kusimba adsorb workpiece.

Kugadzikana kwepamusoro:Nekuda kwehunhu hwezvinhu, iyo wafer pini chuck ine kugadzikana kwakanyanya uye inogona kushanda yakagadzikana kwenguva yakareba.

Deredza kusvibiswa:Ceramic wafer chucks ari kubuda kubva kumagirovha kuenda kumapini kudzikisa nzvimbo yekubata, kuderedza kumwe kusvibiswa uye kugadzirisa warping kugadzirisa.

Process Control

Kururamisa kwakakwirira: 12 inches dhayamita, flatness inodzorwa mukati me5 μm; Kana iwe uchida kunyatsojeka, tapota titumire email.

Shape control: Gadzirisa iyo chuck chimiro zvinoenderana newafer chimiro (isina-uniformity control).

Absorptive kupindura: Yakagadzirirwa dhizaini zvinoenderana nezvakatsanangurwa.

Masevhisi Edu

Sarudzo yewafer pini chuck inofanirwa kutariswa zvinoenderana nezvakawanda zvinhu senge dhayamita inodiwa yemakapu ekuyamwa, huwandu hwemaconvex point, uye chimiro chechuck, uye ita sarudzo yakakodzera zvichienderana nehukuru, huremu hwekushambadza. chinhu uye zvinodiwa zvenzvimbo yekushanda.

Isu takatora precision flat machining tekinoroji, shandisa dhizaini yekugadzira tsika, uye inopa yakanakisa wafer pini chuck kusangana nezvinodiwa nevatengi.

Iyo yakatsetseka chimiro chepini chuck inogona kugadziridzwa zvakasununguka zvichienderana nechimiro chewaferi, uye nzvimbo yeadsorption kana pini patani inogona kugadzirwa kuvandudza adsorption inopindura.

Material: Aluminium oxide ceramic kana silicon carbide inogona kusarudzwa, uye DLC neTeflon inogona kuiswa pamusoro.

Yepamusoro-chaiyo SiC/SSiC wafer pini chucks ari kugadzirwa kuti aonekwe, kuongorora, mafambisirwo anochinjika zvakanyanya, akati sandarara, uye anoshingirira zvakanyanya kunzvimbo dzekushanda dzakaoma.

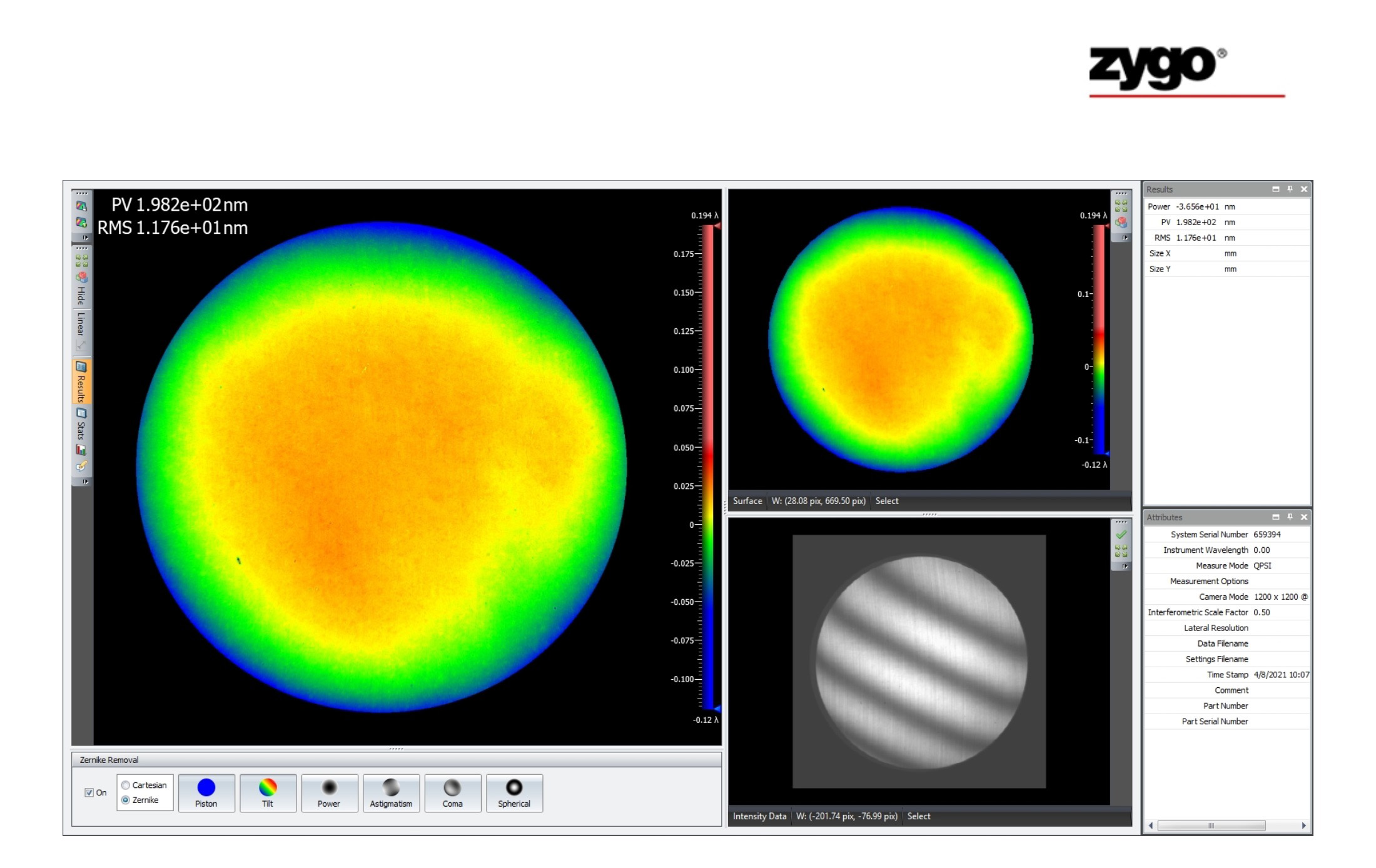

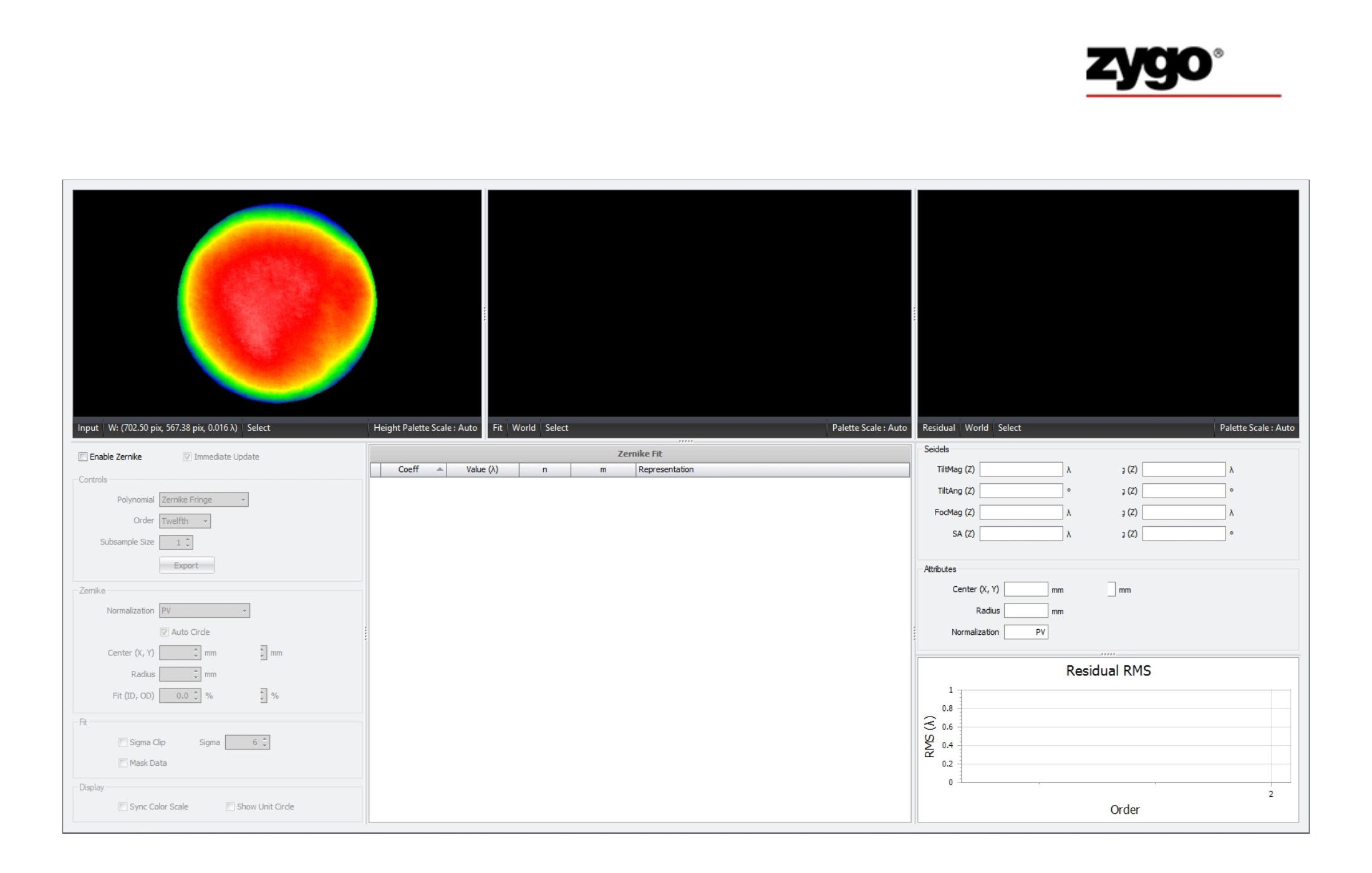

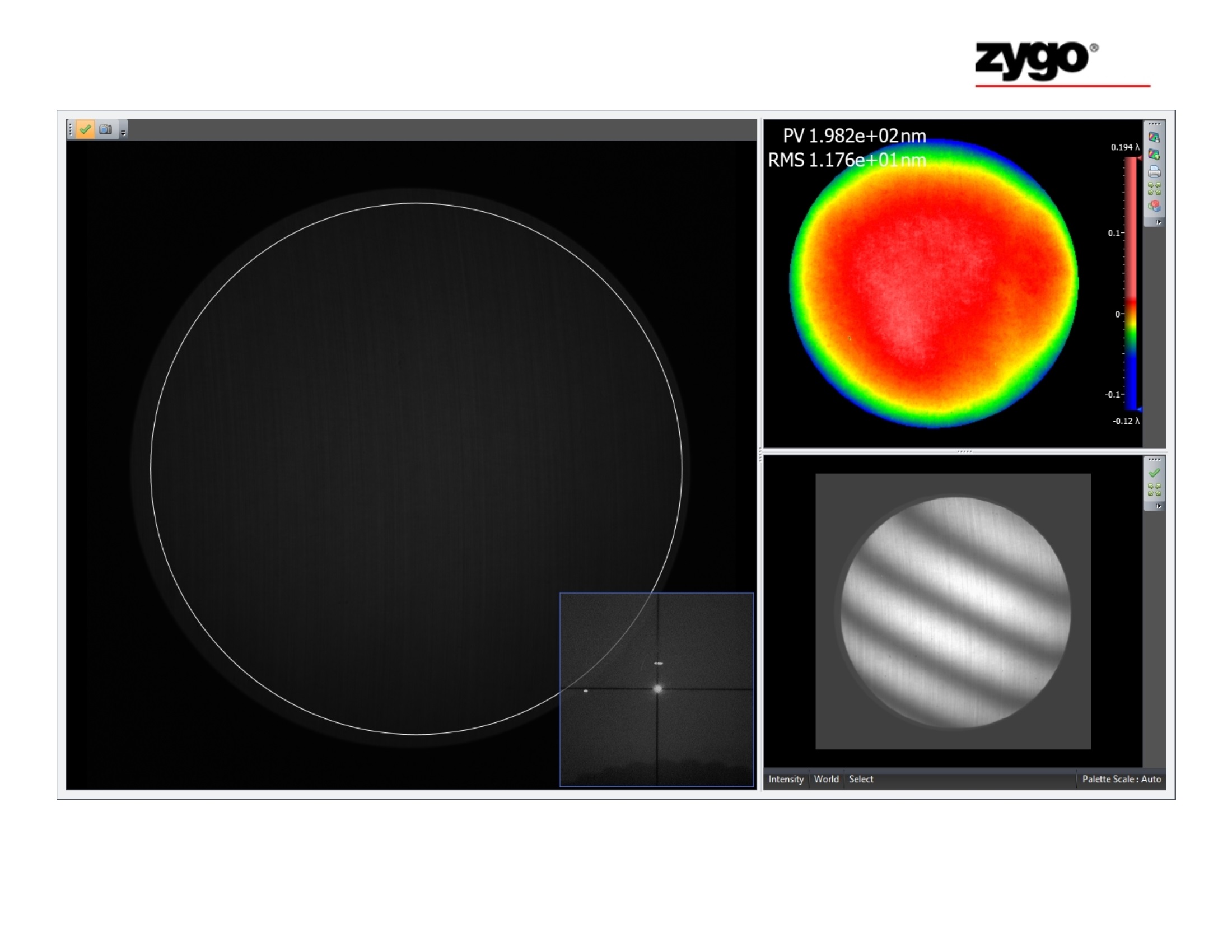

Precision Test Data

Application

Wafer fixation ye semiconductor exposure device; Wafer fixation yewafer yekuongorora mudziyo.

Kumba

Kumba