Wafer pin chuck loo isticmaalo aaladda soo-gaadhista semiconductor iyo aaladda kormeerka wafer

Astaamaha

Iska caabbinta heerkulka sare:Silicon carbide iyo alaabta dhoobada alumina waxay leeyihiin wax qabad heerkul sare oo heer sare ah, waxaa loo isticmaali karaa jawi heerkul sare ah muddo dheer, ma fududa in la gooyo ama dillaaco.

Iska caabin daxalka:waxay u adkeysan kartaa noocyo kala duwan oo kiimiko ah oo daxalka ah, oo ku habboon maaraynta dareeraha wasakhaysan ama gaaska deegaanka shaqada.

Xiro iska caabin:adkaanta sare, oo leh caabbinta xirashada wanaagsan, waxaa loo isticmaali karaa waqti dheer iyada oo aan guul darreyn.

adsorption xoogan:qaab dhismeedka dhibic convex yaraynaysaa aagga xidhiidhka ee koobka nuugista, oo sidaas daraaddeed kordhinta xoogga adsorption halkii aagga unit, iyo si adag u adsorb karaa workpiece ah.

Deganaanshiyo sare:Sababtoo ah sifooyinka maaddada, chuck pin wafer wuxuu leeyahay xasilooni sare wuxuuna u shaqeyn karaa waqti dheer.

Iska yaree wasakhowga:Xirmooyinka dhoobada dhoobada ah ayaa ka soo baxaya godadka ilaa biinanka si ay u yareeyaan aagga xidhiidhka, yareeyaan wasakhowga qaar oo ay hagaajiyaan sixitaanka dagaalka.

Xakamaynta habka

Saxnaanta sare: dhexroorka 12 inji, flatness waxaa lagu xakameynayaa gudaha 5 μm; Haddii aad u baahan tahay saxsanaan dheeri ah, fadlan iimayl noogu soo dir

Xakamaynta qaabka: Ku hagaaji qaabka chuck si waafaqsan qaabka waferka (xakamaynta aan la midka ahayn).

U jawaabida nuugista: Naqshad la habeeyay iyadoo la raacayo qeexitaannada.

Adeegyadayada

Doorashada chuck pin wafer waa in loo tixgeliyaa iyadoo loo eegayo arrimo badan sida dhexroorka loo baahan yahay ee koobabka nuugista, tirada dhibcaha convex, iyo qaabka chuck, oo samee doorasho ku habboon iyadoo loo eegayo cabbirka, miisaanka xajinta shayga iyo shuruudaha deegaanka shaqada.

Waxaanu qaadanay tignoolajiyada farsamaynta fidsan ee saxda ah, waxaanu fulinay nashqad hal abuur leh oo caado u ah, waxaanu bixinay sida ugu fiican ee loo yaqaan wafer chuck si aanu u buuxino shuruudaha adag ee macaamiisha.

Qaabka siman ee pin-chuck si xor ah ayaa loo hagaajin karaa iyadoo loo eegayo qaabka waferka, iyo aagga xayeysiinta ama qaabka biinanka ayaa la habeyn karaa si loo hagaajiyo ka jawaab celinta xayeysiinta.

Qalabka: Aluminium oxide ceramic ama silicon carbide waa la dooran karaa, DLC iyo Teflon ayaa lagu dhejin karaa dusha sare.

Saxeexa sare ee SiC/SSiC wafer chucks ayaa loo sameeyay soo bandhigida waferka, kormeerka, hababka gaadiidka ee aad u dabacsan, aad u fidsan, oo aad ugu adkeysanaya jawi shaqo oo adag.

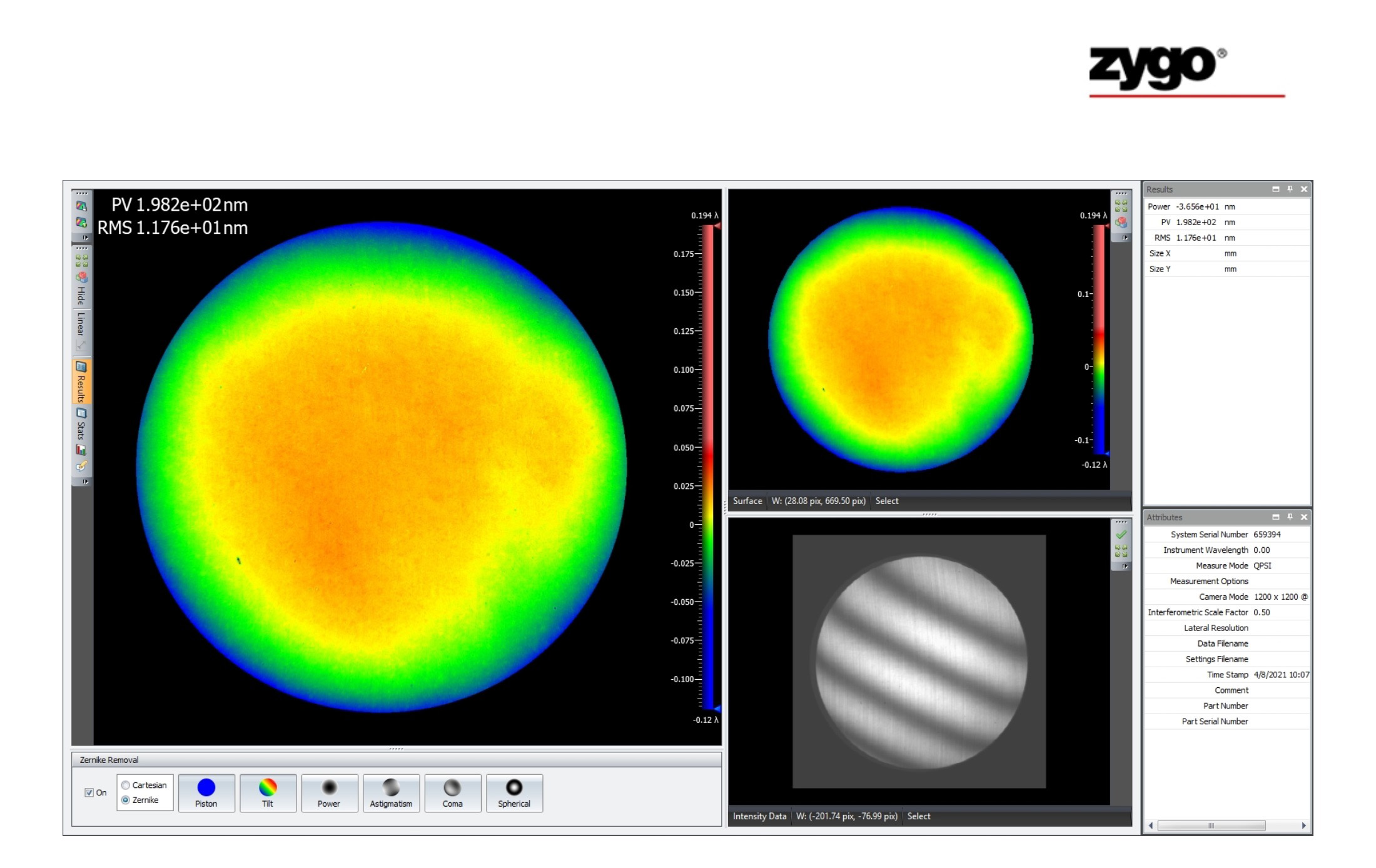

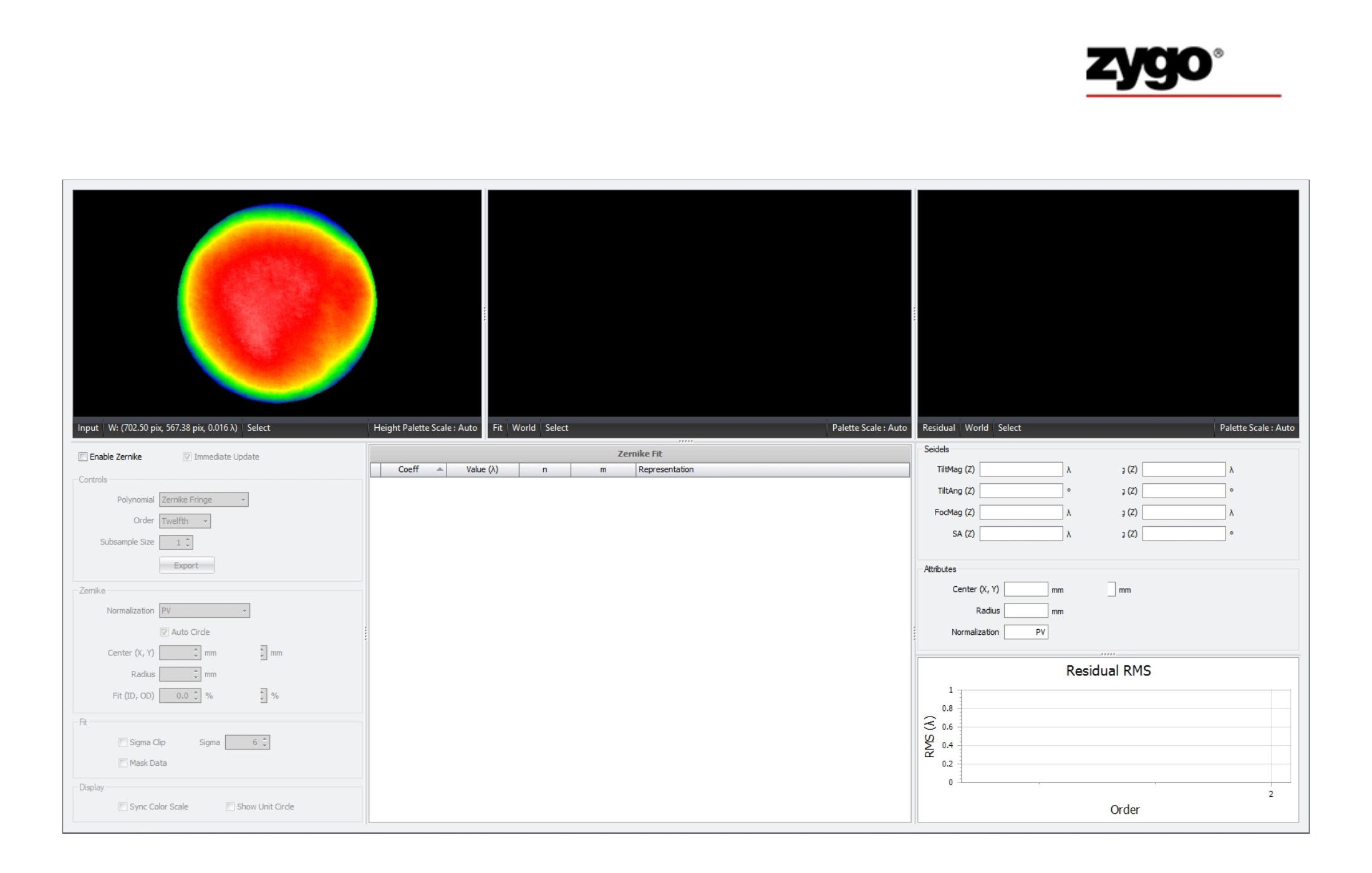

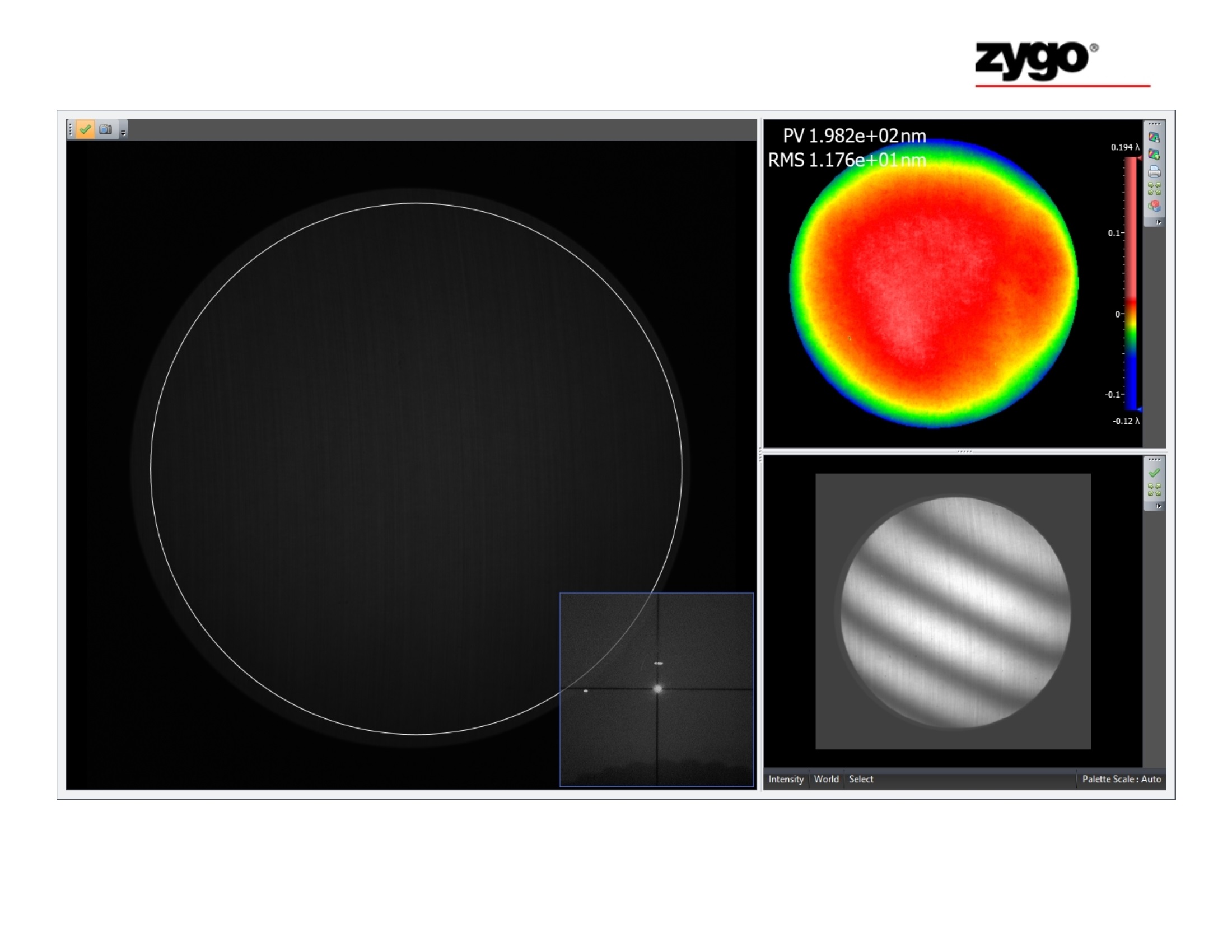

Xogta Imtixaanka Saxda ah

Codsiga

hagaajinta wafer ee qalabka soo-gaadhista semiconductor; Hagaajinta wafer ee qalabka baarista wafer.

Guriga

Guriga