Likaroloana

Tšebelisano | Customization | Boima bo Holimo | Matla a Phahameng a Mehaho | Nako ea Phano e potlakileng | E boloka chelete

Lisebelisoa

Lon-implantation | Thin Film | Etse | Nts'etsopele ea Ts'ebetso | Moqapi oa Lisebelisoa

Moralo le Tlhahiso

12 inch Fab e tlisoa ho netefatsa ts'ebetso ea 'nete, ho fana ka nchafatso le tokiso, le ho netefatsa nts'etsopele le moralo.

Ka lisebelisoa tsa ts'ebetso le nts'etsopele ea theknoloji ea semiconductor le potoloho e kopantsoeng, li-chucks tsa setso tsa motlakase tse sebelisang thepa ea polymer ea organic, li-oxide tsa tšepe le lisebelisoa tsa ceramic joalo ka dielectrics ha li tsamaellane ka botlalo le lisebelisoa tse kang liphaphatha tsa silicon, safire le silicon carbide. Ka hona, li-chucks tsa electrostatic tse lumellanang le moloko oa pele, oa bobeli le oa boraro oa li-semiconductor wafer grippers li tla ntlafala butle-butle.

Polymer Electrostatic Chuck / Heater

Polymer dielectric material (Polymer) hajoale ke lisebelisoa tse sebelisoang ka ho fetesisa tsa electrostatic chuck, ts'ebetso ea eona ea ho itokisa e boetse e le lisebelisoa tse holileng ka ho fetesisa, polymer dielectric kamora kalafo ea phetoho ea polymer, motlakase, mochini, ho hanyetsa mocheso, thepa ea ho hanyetsa halogen e tla ntlafatsoa haholo. Thepa ea dielectric e entsoe ka ts'ebetso e 'ngoe e kopantsoeng, ebe e aroloa ke moroalo o boima oa li-multistage vacuum,' me ho thehoa lesela le teteaneng la dielectric pakeng tsa li-electrode tse ka hare.

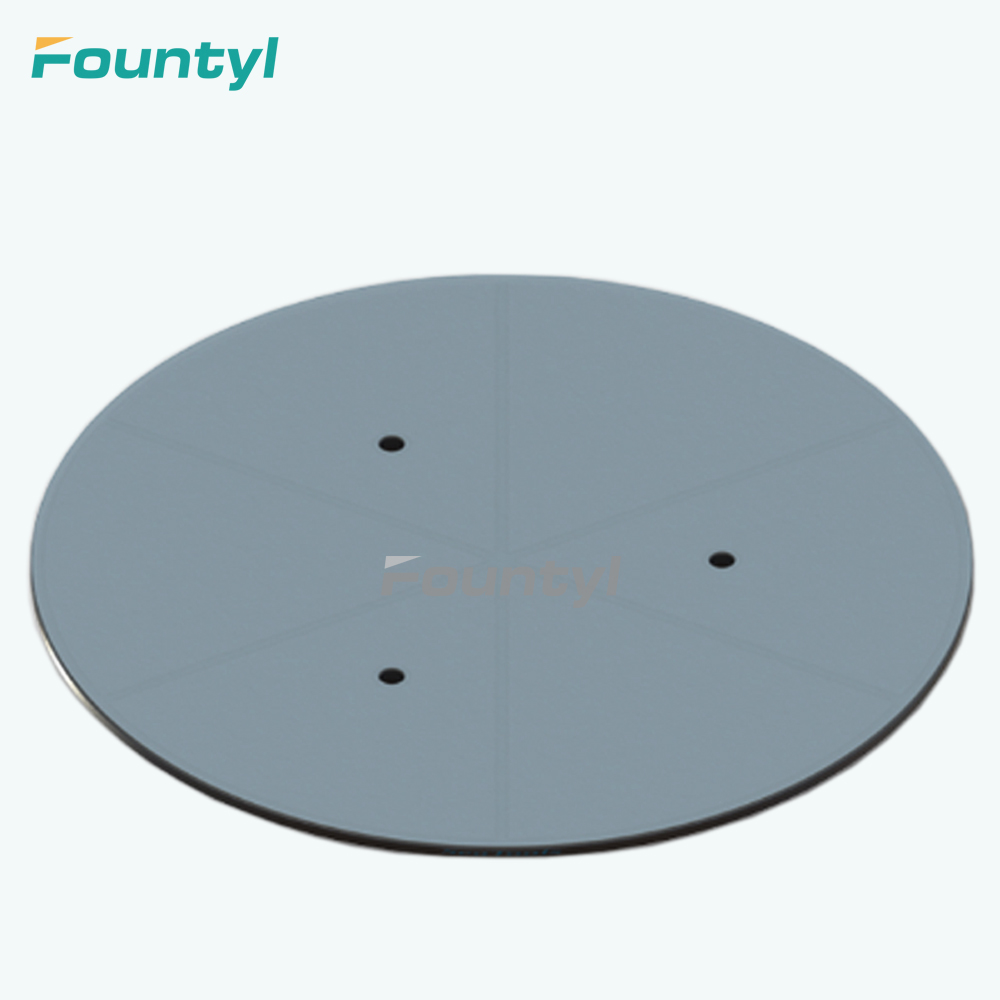

Polymer Electrostatic Chuck

Theknoloji ea phetoho ea polymer e sebelisetsoa ho fumana matla a mangata a ho hanyetsa le ho boloka dielectric kamehla, le ho fumana matla a tsitsitseng haholoanyane.

Lisebelisoa tse phahameng tsa dielectric li ka fokotsa kotsi ea lintho tse nyenyane le ho fokotsa ho tsamaea ha ion.

Mefuta e fapaneng ea lintho tse koalang e ka tsamaellana le ho koaloa ha li-wafers tsa lisebelisoa tse fapaneng.

Ho hanyetsa ho hoholo ha kutu maemong a halogen le plasma.

Ts'ebetso e phahameng ea litšenyehelo, nako e khuts'oane ea ho amoheloa, e loketseng ntlafatso ea ts'ebetso ea sehlahisoa le netefatso ea ntlafatso ea lisebelisoa tse ncha.

Al₂O₃ Electrostatic Chuck

Molumo oa resistivity o laoloa ke theknoloji ea coagulation ceramic le co-firing process ho fumana matla a nako e telele a ho tšoara.

Sebopeho sa ka hare sa mocheso o phahameng oa sintering se teteaneng mme sebopeho sa kristale se tsitsitse, 'me matla a ho tšoara nako e kholoanyane ea mocheso a ka fumanoa.

Ho kopanya ho kopanya ho kopanya ho fokotsa ho falla ha ion.

Ts'ebetso e tšoarellang moeeng oa plasma halogen vacuum.

Lehae

Lehae