Ts'ebetso ea ceramic silicon carbide - Mekhoa, lits'ebetso le mefuta

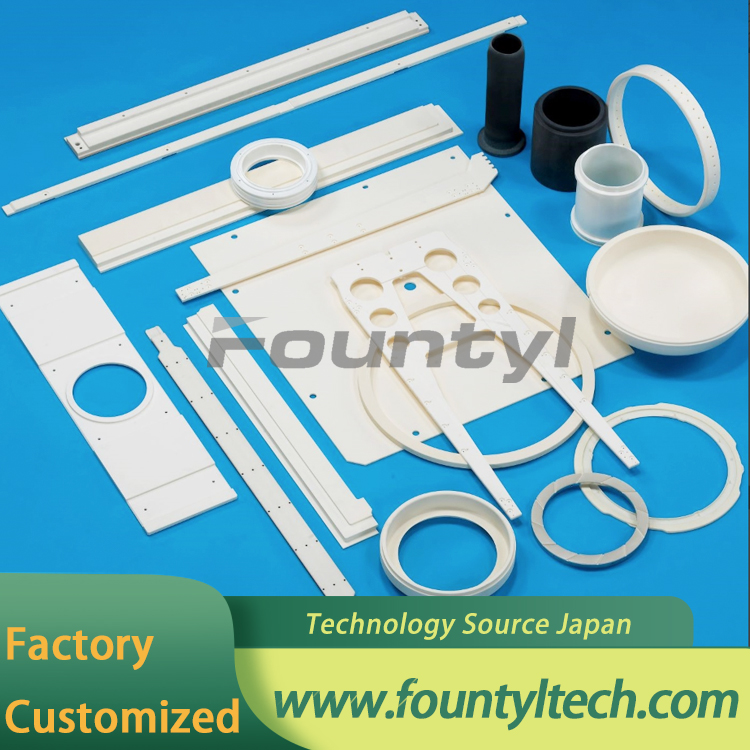

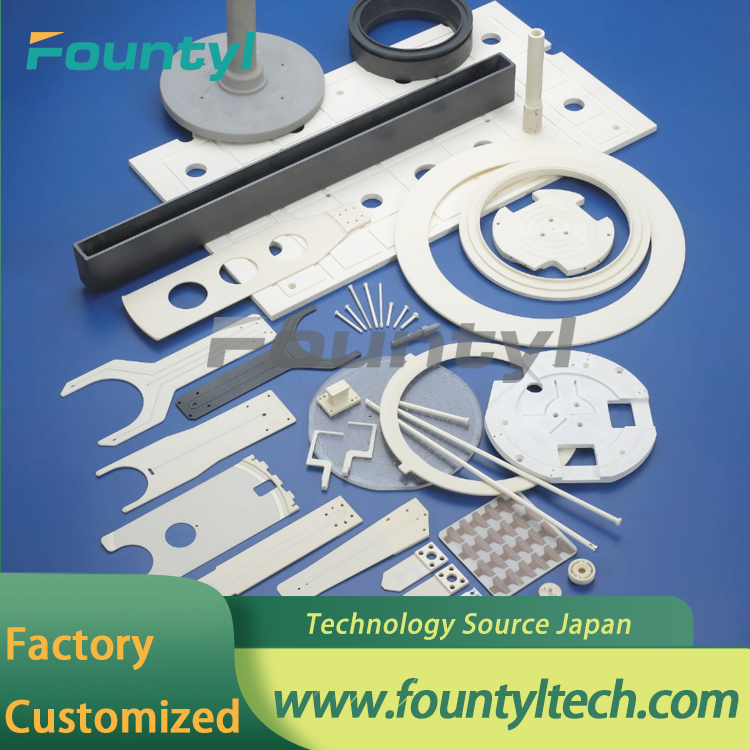

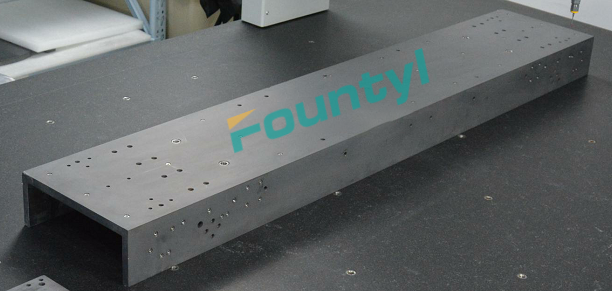

Likarolo tsa silicon carbide tse entsoeng ka mokhoa o nepahetseng tse entsoeng ke Singapore Fountyl Technologies PTE Ltd., Lits'ebetsong tsohle tse hlokang likarolo tsa boenjiniere tse nepahetseng haholo, ke habohlokoa ho hlokomela mathata a ho sebetsana le silicon carbide. Ho sa tsotellehe boleng ba eona bo phahameng ba boima, e ntse e le thepa e batlang e brittle e ka sebetsoang feela ka mekhoa ea ho sila taemane. ka hona, ts'ebetso ea machining ka basebetsi ba nang le tsebo le ba nang le phihlelo e molemo, kaha mekhoa e fosahetseng e ka baka tšenyo e ka tlas'a lefatše le li-micro-cracks tse ka lebisang ho hlōleha pele ho nako hang ha karolo e le tlas'a khatello ea kelello ea ho sebetsa.

Synthetic silicon carbide:

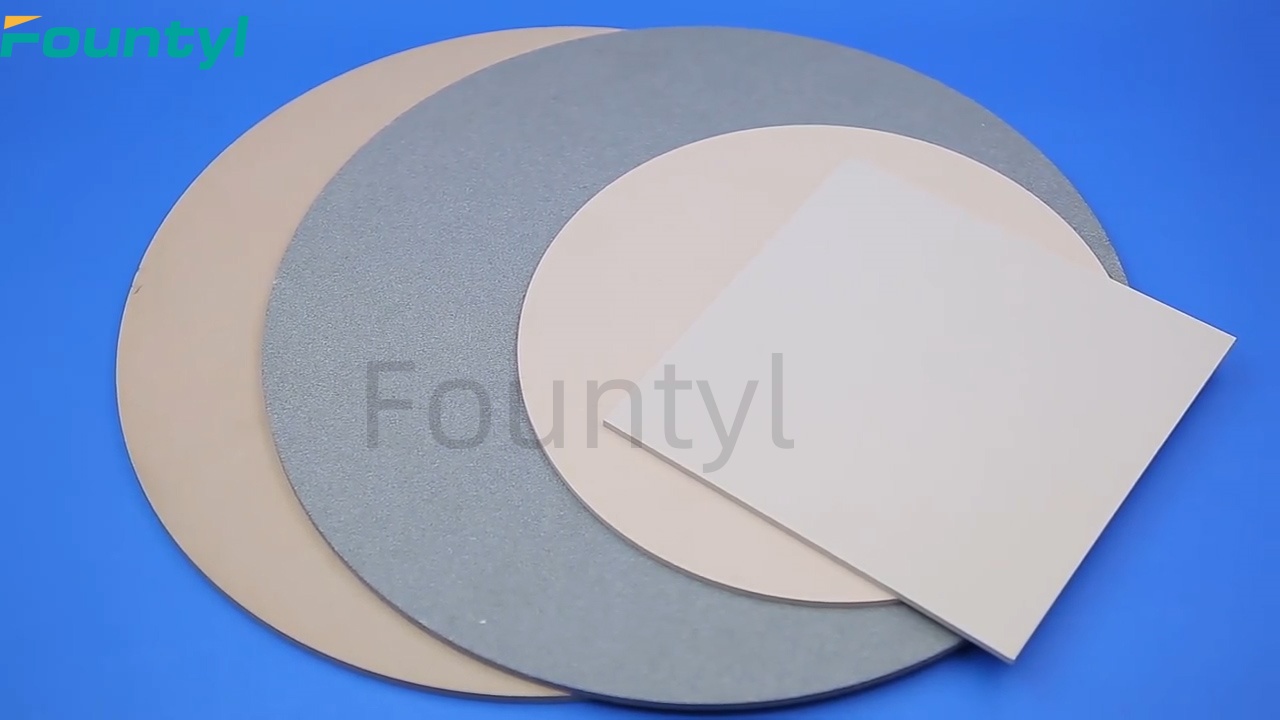

Hangata, silicon carbide e hlahisoa ka mokhoa oa Acheson, o kenyelletsang ho futhumatsa lehlabathe la silica le carbon ho mocheso o phahameng ka sebōping sa ho hanyetsa graphite sa Acheson. E ka etsa phofshoana e ntle kapa makhapetla a tlanngoeng 'me e tlameha ho siloa le ho siloa pele e ka sebelisoa e le phofo e tala. Hang ha silicon carbide e le ka mokhoa oa phofo, lithollo tsa motsoako li ka kopanngoa hammoho ka sintering ho etsa ceramic ea bohlokoa haholo ea boenjiniere e nang le mefuta e mengata ea tšebeliso liindastering tse ngata tsa tlhahiso.

Mefuta ea silicon carbide:

Lihlahisoa tsa silicon carbide bakeng sa lits'ebetso tsa boenjiniere ba khoebo li hlahisoa ka mefuta e meraro. Tsena ke:

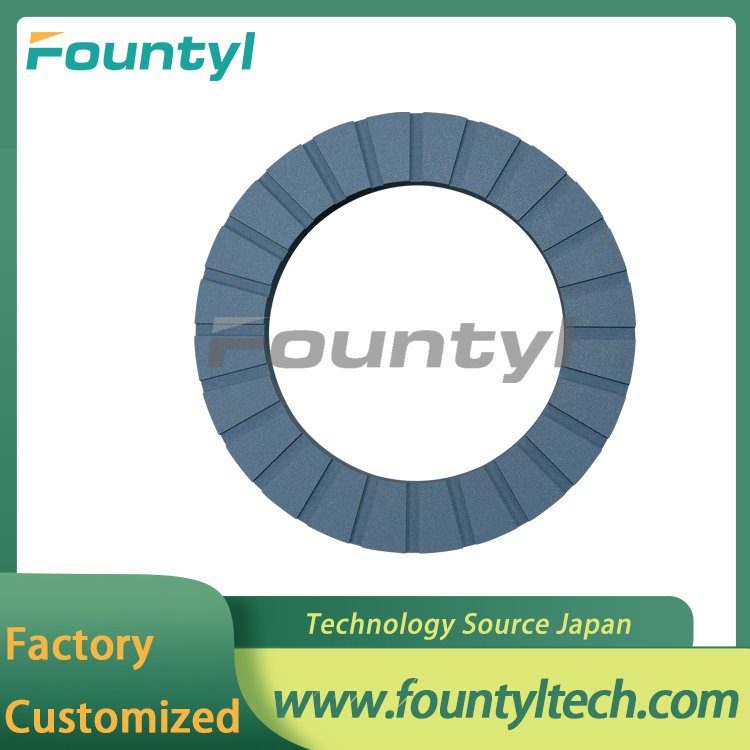

Sintered Silicon Carbide (SSC)

Nitride bonded silicon carbide (NBSC) le

Reactive bonded silicon Carbide (RBSC)

Mefuta e meng ea motsoako e kenyelletsa letsopa-bonded silicon carbide le SiAlon-bonded silicon carbide. Ho boetse ho na le mouoane oa lik'hemik'hale o kentsoeng silicon carbide o bitsoang CVD silicon carbide, e leng mofuta o hloekileng haholo oa motsoako.

E le ho sinter silicon carbide, hoa hlokahala ho eketsa sesebelisoa sa sintering, se thusang ho theha karolo ea metsi ka mocheso oa sintering, ka tsela eo ho tlama lijo-thollo tsa silicon carbide hammoho.

Lisebelisoa tse ka sehloohong tsa silicon carbide:

Silicon carbide e na le lisebelisoa tse ngata liindastering tse fapaneng. Ho thatafala ha eona 'meleng ho etsa hore e be e loketseng bakeng sa ts'ebetso ea abrasive ea ho sila, honing, sandblasting le waterjet cutting.

Silicon carbide e khona ho mamella mocheso o phahameng haholo ntle le ho robeha kapa ho holofala mme e sebelisoa ho etsa li-brake disc tsa ceramic bakeng sa likoloi tsa lipapali. E boetse e sebelisoa ka liphahlo tse thibelang likulo e le thepa ea lihlomo le lisebelisoa tsa ho tiisa bakeng sa li-pump shaft seals, moo hangata e sebetsang ka lebelo le phahameng ha e kopana le litiiso tse tšoanang tsa silicon carbide. E 'ngoe ea melemo e ka sehloohong ea lisebelisoa tsena ke mocheso o phahameng oa mocheso oa silicon carbide, o khonang ho felisa mocheso o tsitsitseng o hlahisoang ke sebopeho sa likhohlano.

Boima bo phahameng ba thepa bo lumella hore e sebelisoe lits'ebetsong tse ngata tsa boenjiniere tse hlokang boemo bo phahameng ba ho thella, khoholeho le moaparo o senyang. Hangata sena se ka sebelisoa bakeng sa likarolo tse sebelisoang lipompong, kapa mohlala li-valve lits'ebetsong tsa oli ea oli, moo likarolo tsa tšepe tse tloaelehileng li ka bontšang litekanyetso tse feteletseng tsa ho apara, tse lebisang ho hlōleha ka potlako.

Motsoako ona o na le lisebelisoa tse ikhethang tsa motlakase joalo ka semiconductor, e leng se etsang hore e be se loketseng bakeng sa ho etsa li-diode tse hlahisang mabone a phahameng ka ho fetesisa le a matla a phahameng, li-MOSFET le li-thyristors bakeng sa li-switches tse matla haholo.

Thepa e na le coefficient e tlase ea ho atolosoa ha mocheso, ho thatafala, ho tiea le ho tsamaisa mocheso, e leng se etsang hore e be seipone se loketseng bakeng sa libonela-hōle tsa linaleli. Lithapo tsa silicon carbide, tse bitsoang li-filaments, li sebelisetsoa ho lekanya mocheso oa khase ka mokhoa oa optical o bitsoang filament pyrometry.

E boetse e sebelisetsoa ho futhumatsa lintho tse hlokang ho ikamahanya le mocheso o phahameng haholo. E bile e sebelisoa matla a nyutlelie ho fana ka tšehetso ea sebopeho bakeng sa li-reactors tse pholileng ka mocheso o phahameng oa mocheso.

Lehae

Lehae