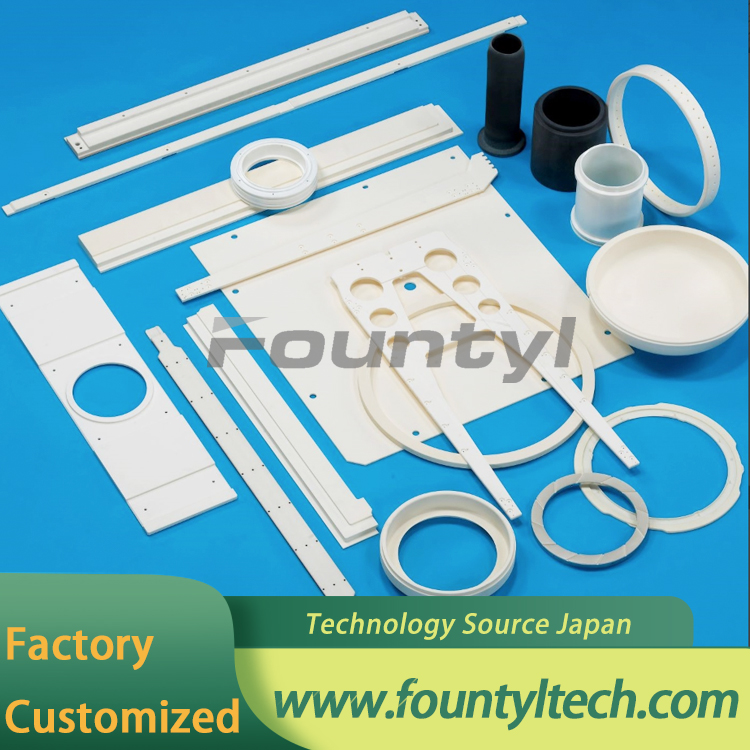

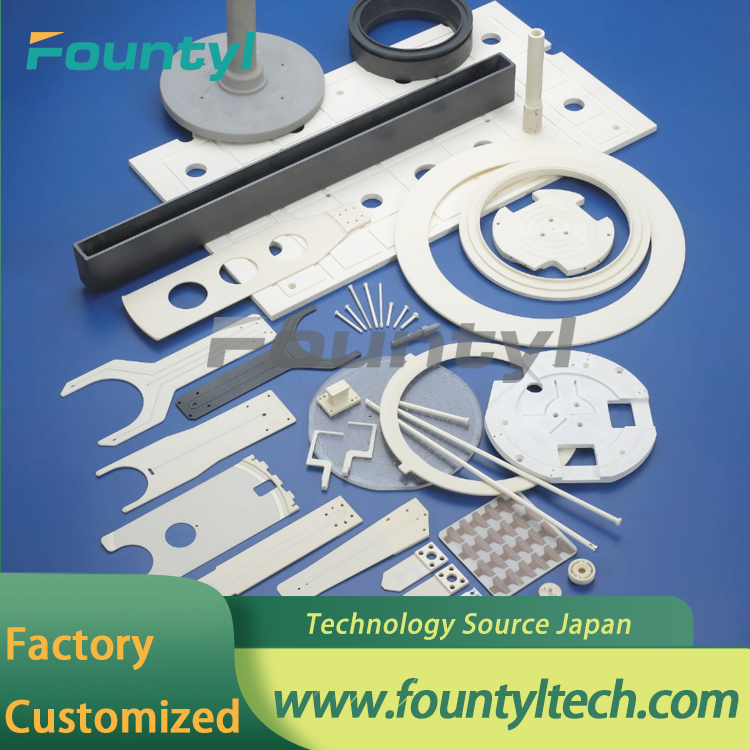

FOUNTYL major product scop of precision ceramic

Management team of Fountyl Technologies PTE Ltd has more than 20 years of semiconductor/panel /MEMS engineering experience, familiar with various materials in the industry application; With reliable materials, stable quality and high-end precision manufacturing technology as the core.

What are the methods of precision ceramic processing?

Precision ceramic materials have different processing methods according to different performance requirements. At present, the main processing methods include mechanical processing, electrical processing, supersonic processing, laser processing and composite processing. The following is a brief introduction to the machining methods of precision ceramics.

Application of microporous ceramics

Microporous ceramics have the advantages of adsorption, permeability, corrosion resistance, environmental compatibility, biocompatibility, unique physical and chemical properties of the surface structure and are widely used in all kinds of liquid filtration, gas filtration and fixed biological enzyme carriers and biological adaptive carriers.

Introduction to microporous ceramics technology

Different from the previous universal cognition of "ceramics", "microporous ceramics" is an industrial material that can be seen everywhere in the industry. When it comes to microporous ceramics, there must be some people who feel very strange to this concept, what is it? What is the difference with our conventional understanding of "ceramics"?

Quality management for ceramic vacuum chuck

FOUNTYL Technologies PTE Ltd is a professional company specializing in the production of porous ceramics, ceramic vacuum chuck, ceramic arms, with many years of industry experience, has a good reputation in the industry, how does Fountyl control the quality of ceramic vacuum chuck?

Why are our porous ceramic vacuum chuck recognized by many engineers and designers?

Why are porous ceramic vacuum chuck recognized by many engineers and designers? What are the characteristics of Fountyl porous ceramic vacuum chuck?

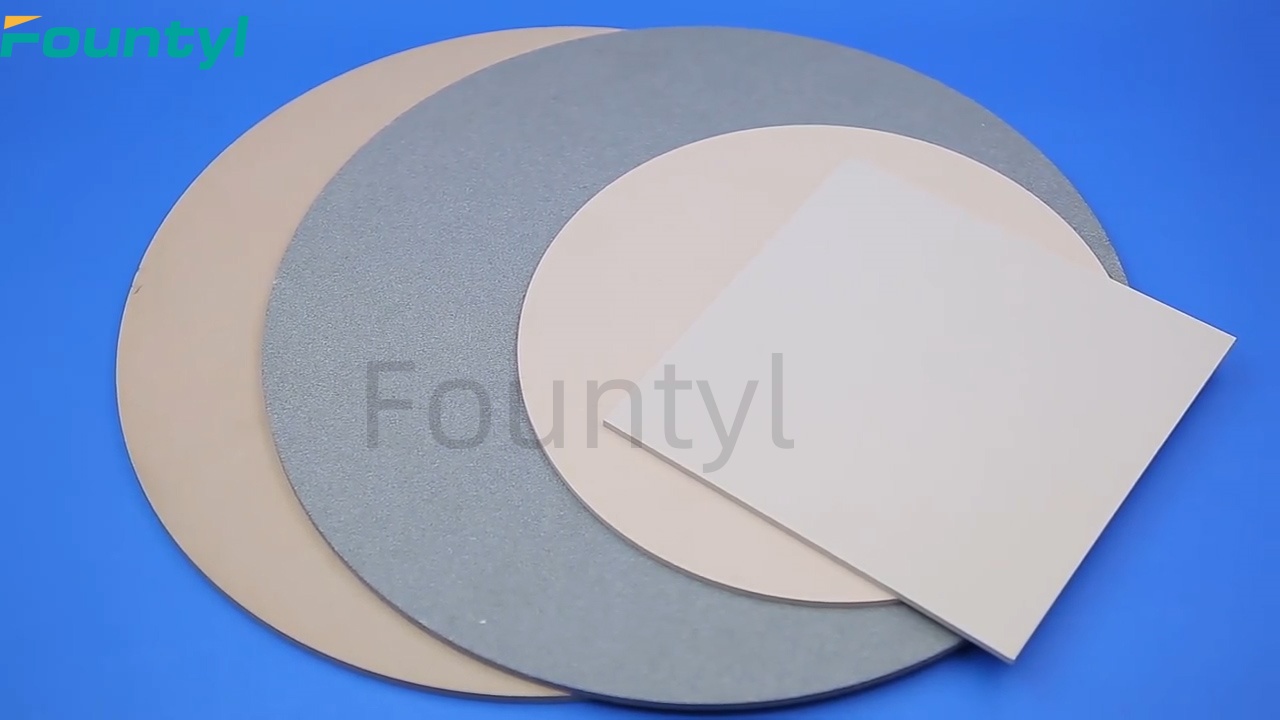

Application of porous ceramic vacuum chuck

In the semiconductor and optoelectronics industry, very thin wafers are usually placed on advanced ceramic breathable chucks, attached to a vacuum generator, and fixed by vacuum suction. Fountyl Technologies PTE Ltd- special ceramic chuck for silicon wafer waxing, thinning, wax removal, cleaning, cutting processes.

Application of ceramic robotic arm

Ceramic end effector (ceramic robotic arm) are used to operate and carry silicon wafers throughout the production of semiconductor processes. It is capable of handling large wafers and can be designed with a vacuum channel to carry the part.

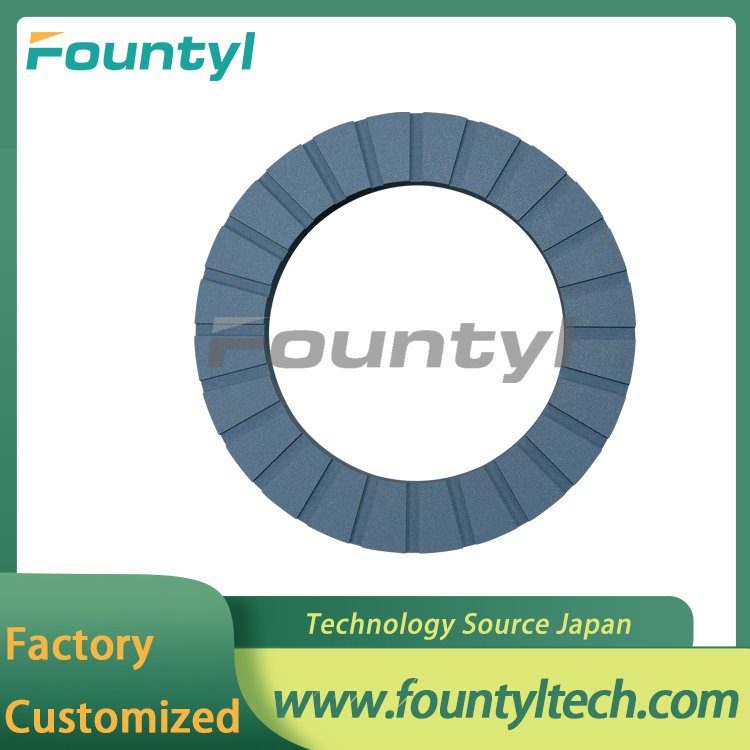

Introduction to porous ceramics

Porous ceramic materials with vary according to the pore size. for ultramicropore ceramics and extremely small pores, the pore size is several times of the molecular diameter. During adsorption, the pore wall surrounds the adsorption molecules, and the adsorption force in the pore is very strong.

Semiconductor precision ceramic vacuum chuck

High density ceramic vacuum chuck (porous ceramic vacuum chuck), a special porous ceramic material with a pore size of 2 to 3 microns, is not easy to block, high vacuum force, part of the area adsorption, but also can be used as an air floating platform, widely used in semiconductors, panels, laser process and non-contact linear slide.